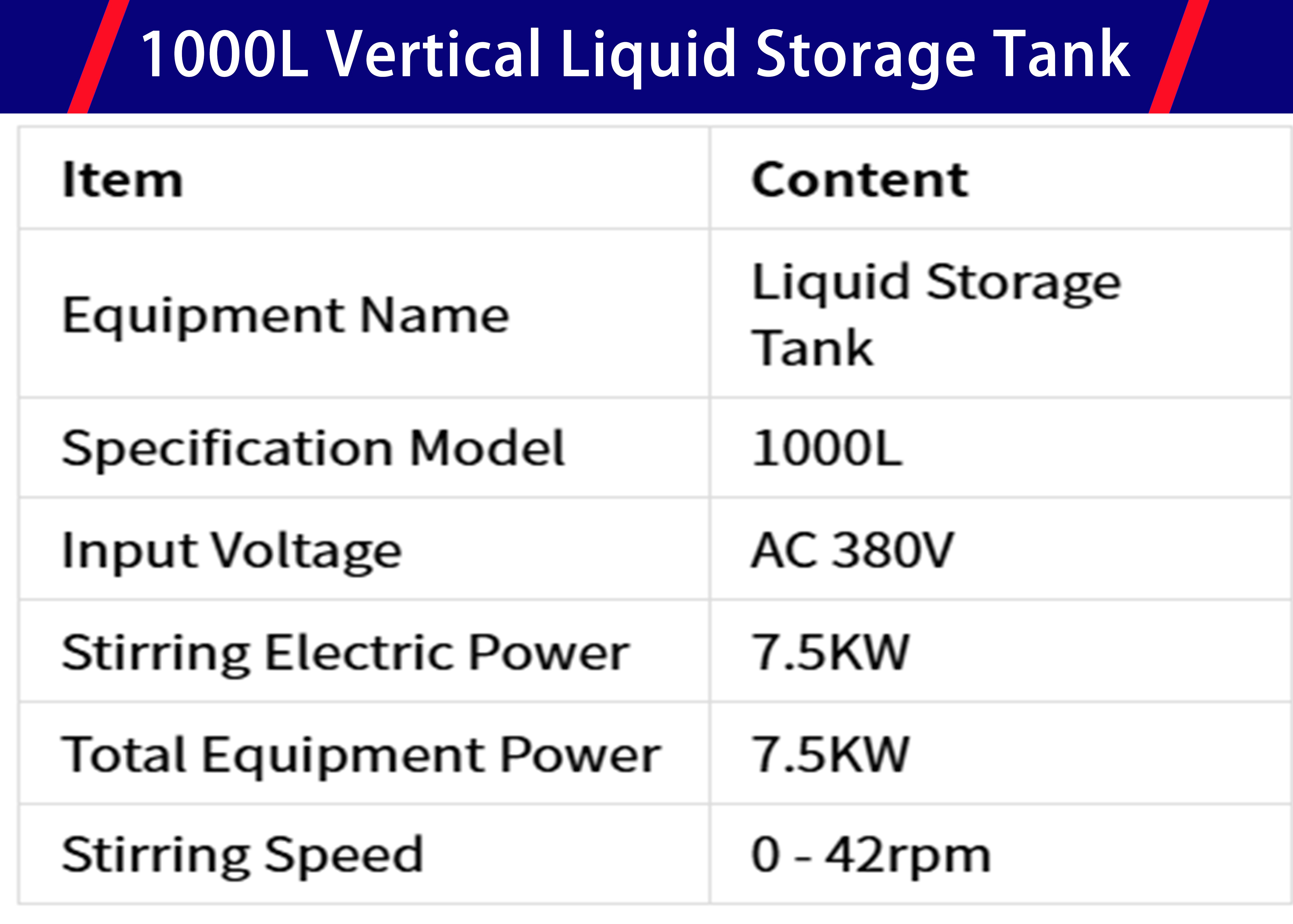

1000L Vertical Liquid Storage Tank

The 1000L Vertical Liquid Storage Tank is a space-efficient solution for industrial liquid storage. Its vertical design saves floor space, fitting well in compact areas.Made of stainless steel (304/316L), PE, or carbon steel, it suits diverse needs—stainless steel for food/pharmaceuticals (hygienic, corrosion-resistant), PE for water/non-corrosive chemicals (UV-resistant), carbon steel for oils/coolants.Equipped with sealed tops (anti-contamination), level gauges (volume monitoring), and bottom outlets (easy drainage), it meets safety standards (ASME/ISO). Ideal for small-to-medium ops, ensuring reliable liquid management.

Always on time

Always on time Acceptable price

Acceptable price Excellent quality

Excellent quality

Description

Feature&Application

Factory Strength

The 1000L Vertical Liquid Storage Tank stands out as a space-efficient and reliable choice for storing, handling, and managing liquids across diverse industries. Designed with a vertical orientation, this tank optimizes floor space utilization—critical for facilities where horizontal area is limited—while delivering consistent performance for both indoor and outdoor applications.

Crafted from high-quality materials tailored to specific use cases, the tank is commonly available in food-grade stainless steel (304/316L), polyethylene (PE), or carbon steel. Stainless steel variants excel in pharmaceutical, food, and beverage industries, offering corrosion resistance, compliance with hygiene standards (such as FDA or EU 10/2011), and easy sanitization. PE models, meanwhile, are ideal for storing water, chemicals (non-corrosive), or agricultural fluids, boasting lightweight durability, UV resistance for outdoor use, and low maintenance requirements. Carbon steel options, often coated with anti-rust finishes, suit industrial bulk storage of oils, coolants, or neutral liquids, balancing strength and cost-effectiveness.Functionality is at the core of its design. The vertical structure ensures efficient liquid distribution, with a sealed top (equipped with pressure relief valves for safety) to prevent contamination, evaporation, or leakage. Most models include a bottom outlet for easy drainage, a side-mounted level gauge for real-time volume monitoring, and optional fittings (such as inlet ports, sampling valves, or agitator mounts) to adapt to custom workflows. Its 1000L capacity strikes a perfect balance between compact size and storage volume, making it suitable for small to medium-scale operations—from laboratories and cafes to manufacturing plants and agricultural farms.

Safety and durability are non-negotiable. The tank is engineered to withstand static and dynamic loads, with reinforced bases for stability and compliance with industry standards (such as ASME, ISO, or local safety regulations). For hazardous liquids, optional flame arrestors or chemical-resistant linings can be added to mitigate risks.

In summary, the 1000L Vertical Liquid Storage Tank is a adaptable, safe, and space-saving solution that meets the diverse needs of liquid storage—whether for food, chemicals, water, or industrial fluids—helping businesses streamline operations and ensure product integrity.

Features

The 1000L Vertical Liquid Storage Tank is a versatile industrial storage solution, distinguished by design and performance tailored for efficient liquid management. A primary feature is its vertical structure optimized for space efficiency. Unlike horizontal tanks that occupy large floor areas, its vertical orientation maximizes vertical space utilization—critical for factories or facilities with limited ground space. The tank’s tall, narrow profile (typically 1.2–1.5m in diameter and 1.8–2.2m in height) allows it to fit in compact corners while still holding 1000L of liquid, making it ideal for small-to-medium industrial sites.

Another key feature is its durable, corrosion-resistant construction. Most models are crafted from 304 or 316 stainless steel—materials that resist rust, chemical erosion, and degradation from harsh liquids (e.g., acids, alkalis, or industrial solvents). For specialized needs (e.g., storing food-grade liquids or pharmaceuticals), the tank’s interior is polished to a smooth finish, preventing liquid residue buildup and ensuring compliance with hygiene standards (such as FDA or GMP). Additionally, the tank’s base is reinforced with a stable support frame, preventing tipping even when fully loaded (1000L of water weighs approximately 1000kg).

It also offers user-friendly design for easy operation and maintenance. Equipped with essential accessories: a top-mounted inlet for easy liquid filling, a bottom outlet with a valve for controlled dispensing, and level indicators (sight glasses or digital sensors) to monitor liquid volume in real time—eliminating the need for manual measurement. Many models include a manhole or access port for periodic cleaning, while some add pressure relief valves for safe storage of volatile liquids. These features simplify daily use and reduce maintenance time, making the tank a low-effort storage solution.

Application Areas

The 1000L Vertical Liquid Storage Tank is widely used across industries requiring reliable medium-capacity liquid storage. In the chemical industry, it serves as a core storage unit for industrial chemicals such as solvents, mineral oils, and liquid detergents. Chemical manufacturers use the tank to store raw materials before production or finished products awaiting distribution—its stainless steel construction ensures chemicals do not react with the tank material, preventing contamination or product degradation. The 1000L capacity is ideal for medium-scale chemical plants, balancing storage needs with space constraints.

In the food and beverage industry, it is essential for storing food-grade liquids like fruit juices, syrups, edible oils, and dairy by-products. For juice processors, the tank safely stores freshly pressed juice before pasteurization; its smooth interior prevents bacterial growth, while the vertical design saves space in busy production lines. For edible oil manufacturers, the tank’s corrosion resistance ensures oil quality remains uncompromised, and the bottom outlet allows easy transfer to filling machines. It also complies with food safety regulations, making it suitable for direct contact with consumable liquids.

The water treatment and environmental sector relies on it for storing treated water, wastewater, or chemical reagents (e.g., coagulants, disinfectants). Water treatment plants use the tank to hold treated water before distribution to small communities, while the 1000L capacity matches the needs of local or on-site treatment facilities. For reagent storage, the tank’s chemical resistance prevents leaks or reactions, ensuring safe handling of substances used in water purification.

Additionally, in the pharmaceutical industry, it stores non-sterile liquid ingredients (e.g., solvents for drug formulation or cleaning solutions for equipment). The tank’s polished stainless steel interior meets GMP standards, avoiding cross-contamination, and its level indicators ensure accurate ingredient dosing for drug production. This versatility across chemical, food, water treatment, and pharmaceutical sectors makes the 1000L Vertical Liquid Storage Tank a indispensable asset for medium-capacity liquid storage needs.

Gangben Mixer Manufacturer specializes in the research, development, production, and sales of mixing machines and filling machines. Its main products include vacuum emulsifying mixers, high-shear emulsifying mixers, vacuum homogenizing emulsifiers, filling and sealing machines, and liquid filling production lines. Equipped with modern production workshops and environments, we adopt advanced equipment manufacturing technologies and strict process quality management and control measures to ensure that all products are free from defects before leaving the factory.

Gangben Mixer Factory has obtained multiple patents for the research and development of emulsifying machines and planetary mixers, as well as ISO quality management system certification and international CE certification. Our products meet quality standards with a reliable quality guarantee. We are committed to manufacturing high-quality mixing machinery to enhance your production efficiency and reduce costs for your company.

-

Prev300L Capacity Heating Mixer

-

NextNone

English

English Russian

Russian French

French Spanish

Spanish Portuguese

Portuguese Korean

Korean Japanese

Japanese Thai

Thai