-

Is the rotational speed of a laboratory emulsifier the higher the better?

Nov 19, 2025The answer is no. When the rotational speed reaches an excessively high value, it tends to impede fluid movement. The flow rate becomes extremely low while heat generation rises sharply, and some mate... }}Learn more -

Which Filling and Sealing Machine is Best? Key Factors to Consider

Oct 30, 2025With the comprehensive development and application of science and technology, the filling and sealing machine industry has achieved better growth, with a wide variety of filling equipment emerging con... }}Learn more -

What is the difference between a homogenizing emulsifier and a planetary mixer?

Oct 28, 2025Many customers have questions when choosing between these two types of equipment. In terms of the equipment themselves, both function to homogenize, disperse, stir, and emulsify raw materials. However... }}Learn more -

Vacuum Emulsifier: How to Achieve 99% Bubble-Free Emulsion through Negative Pressure Environment?

Oct 23, 2025In industries such as cosmetics, pharmaceuticals, food, and specialty chemicals, achieving bubble-free emulsions is critical for product stability, shelf life, and performance. Traditional emuls... }}Learn more -

Vacuum Homogenizing Mixer: How to Achieve Nanoscale Particle Dispersion through Negative Pressure Environment?

Oct 23, 2025In industries ranging from cosmetics and pharmaceuticals to food and advanced materials, achieving nanoscale particle dispersion is critical for product performance, stability, and bioavailability.&nb... }}Learn more -

Can Vacuum Planetary Mixers Achieve Dead-Corner-Free Mixing?

Oct 13, 2025With the advent of vacuum planetary mixers, they have gradually replaced traditional manual mixing operations. While increasing output, they greatly improve production efficiency, stir materials to a ... }}Learn more -

What Makes Vacuum Dual-Planetary Mixers Stand Out?

Oct 13, 2025Mixers are widely used in daily life and play an indispensable role in industries, food processing, and other fields. From making soybean milk to squeezing fruit juice, mixers are powerful tools that ... }}Learn more -

What to Do If the Bearing Bush of a Vacuum Homogenizing Emulsifier Is Damaged?

Oct 11, 2025As we all know, vacuum homogenizing emulsifiers boast high production efficiency, excellent performance, and easy, reliable operation. They help enterprises save significant labor, production, and tim... }}Learn more -

What Are the Future Technological Development Trends of Vacuum Emulsifiers?

Oct 07, 2025The future technological development trends of vacuum emulsifiers are mainly reflected in the improvement of intelligence and automation, high efficiency, environmental protection and energy conservat... }}Learn more -

How Can Chinese Local Steel Manufacturers Enhance High-End R&D Capabilities for Vacuum Emulsifiers?

Sep 29, 2025As core upstream players in the vacuum emulsifier supply chain, Chinese local steel manufacturers can boost the high-end R&D capabilities of vacuum emulsifiers (focused on optimizing steel-based c... }}Learn more -

How to Precisely Control the Temperature of a Vacuum Emulsifying Mixer?

Dec 27, 2023Controlling the temperature of a vacuum emulsifying mixer is essential for achieving optimal performance and consistency in producing cream, mayonnaise, and other similar products. Below are key steps... }}Learn more -

What Is a High-Shear Homogenizer Emulsifying Mixer?

Dec 22, 2023A high-shear homogenizer emulsifying mixer is a specialized mixing device that utilizes intense shear force to achieve efficient emulsification and mixing of various substances. It is widely used in t... }}Learn more -

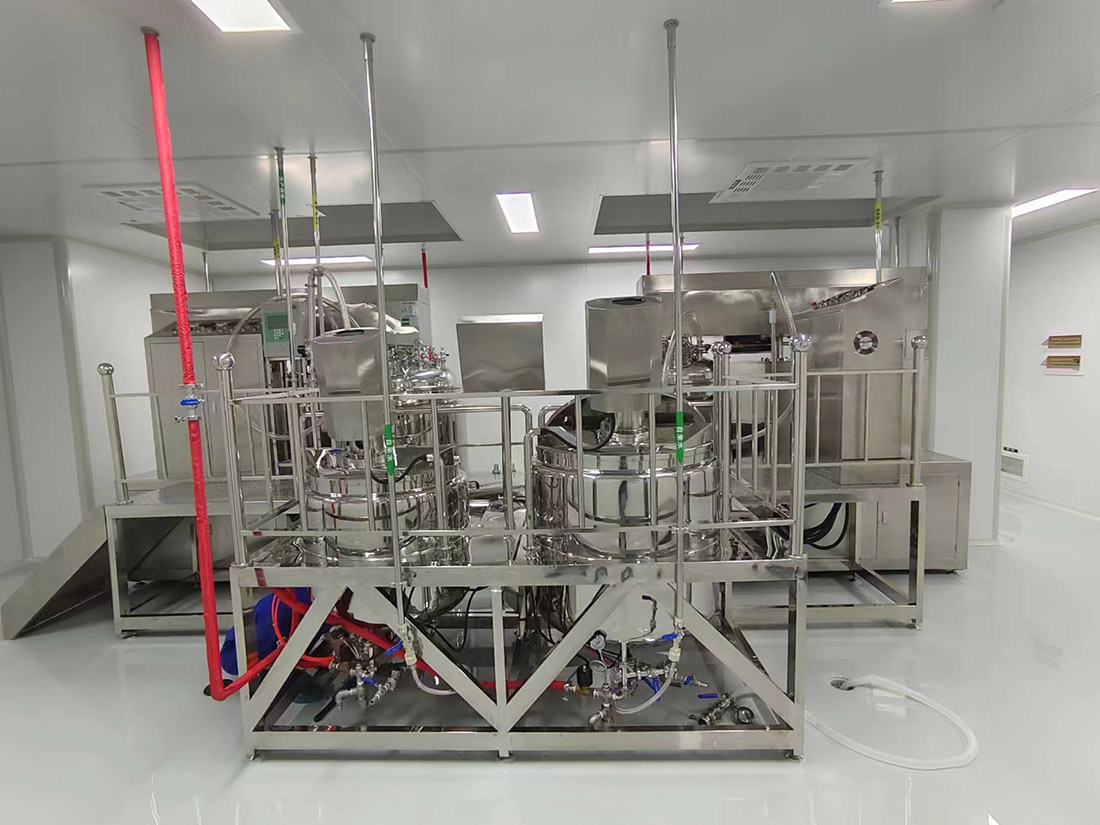

What Is a Vacuum Emulsifying Mixer?

Dec 22, 2023A vacuum emulsifying mixer is a specialized mixing device that operates under vacuum conditions to achieve emulsification and mixing of various substances. It is widely used in industries such as cosm... }}Learn more -

Which Industries Are Vacuum Homogenizer Emulsifying Mixers Used For?

Dec 22, 2023A vacuum homogenizer emulsifying mixer is a versatile device widely used across multiple industries, with particular prominence in cosmetics, pharmaceuticals, food, and chemicals. It integrates the fu... }}Learn more -

Which Is the Best Manufacturer of Vacuum Homogenizer Emulsifying Mixers in China?

Dec 17, 2023When selecting a manufacturer for vacuum homogenizer emulsifying mixers in China, determining which company offers the best overall value requires evaluating multiple core factors. Below are the key c... }}Learn more

News

- Latest News

- Solutions

- FAQ

Recommend Products

-

5L Vacuum Emulsifying Homogenizer Mixer

5L Vacuum Emulsifying Homogenizer MixerThe 5L vacuum emulsifying mixer is a device designed for emulsifying and mixing various substances in a vacuum environment. This equipment is equipped with a mixing tank with a capacity of 5 liters and is widely applied in industries such as food, pharmaceuticals, cosmetics, and pesticides.

-

5L PLC-Screen Vacuum Emulsifying Mixer

5L PLC-Screen Vacuum Emulsifying MixerThe 5L PLC-Screen Vacuum Emulsifying Mixer is a device designed for emulsifying and mixing various substances in a vacuum environment. This equipment is equipped with a mixing tank with a capacity of 5 liters and is widely applied in industries such as food, pharmaceuticals, cosmetics, and pesticides.

-

10L Vacuum Emulsifying Homogenizer Mixer

10L Vacuum Emulsifying Homogenizer MixerThe 10L Vacuum Emulsifying Mixer is a device used for emulsifying and mixing various substances in a vacuum environment. It is commonly used in industries such as food, cosmetics, and pharmaceuticals.

English

English Russian

Russian French

French Spanish

Spanish Portuguese

Portuguese Korean

Korean Japanese

Japanese Thai

Thai