150L Double Planetary Dispersion Mixer

The 150L Double Planetary Dispersion Mixer is an industrial-grade high-efficiency mixing equipment with an effective volume of 150 liters, suitable for medium-batch production. It adopts a synergistic operation mode of double planetary agitation and high-speed dispersion: the agitator paddles combine revolution around the container center with self-rotation, while the dispersion disk performs high-speed shearing. This enables rapid uniform mixing, dispersion and refinement of materials. Widely used in coatings, adhesives, polymer materials and other fields, it handles multi-phase systems like solid-liquid and liquid-liquid, integrating mixing efficiency and material quality, serving as a core device in fine chemical production.

Always on time

Always on time Acceptable price

Acceptable price Excellent quality

Excellent quality

Description

Feature&Application

Factory Strength

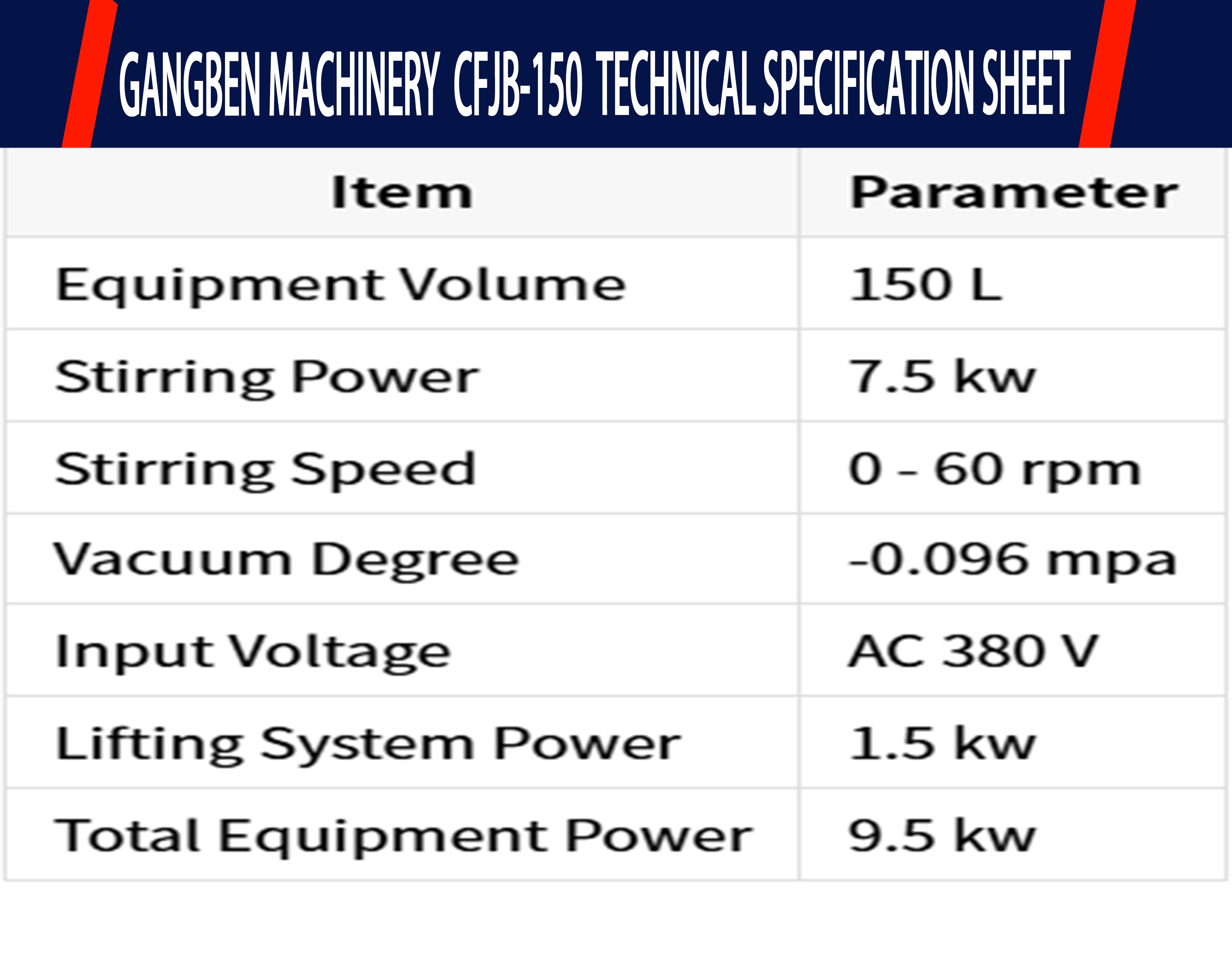

The 150L Double Planetary Dispersion Mixeris a multi-functional mixing and dispersing equipment designed for medium-batch industrial production. With its core parameter of 150-liter effective volume, it balances production efficiency and operational flexibility, becoming a key equipment in fine chemical fields such as coatings, inks, adhesives, resins, and polymer composites.

Its core advantage stems from the unique "double planetary agitation + high-speed dispersion" composite working mechanism. The equipment is equipped with two sets of planetary agitator paddles. During operation, they revolve around the container center while rotating at high speed themselves, creating strong convection, shearing and turning effects. This allows deep penetration into all areas of the material, eliminating mixing dead zones. Combined with an independent high-speed dispersion disk (rotating at up to several thousand RPM), it can efficiently shear, grind and refine particles in the material, quickly breaking up agglomerates to achieve uniform mixing and dispersion of solid-liquid, liquid-liquid and solid-solid multi-phase materials.

The structural design integrates practicality and safety: the mixing container is made of stainless steel, featuring corrosion resistance and easy cleaning, compatible with materials of different chemical properties. It is equipped with a frequency conversion speed control system, which flexibly adjusts agitation and dispersion speeds according to material viscosity and mixing stages, adapting to diverse material forms from low-viscosity liquids to high-viscosity pastes. Additionally, some models offer an optional vacuum system, enabling operation under negative pressure to effectively remove bubbles from materials, improve the density and smoothness of final products, and meet the production requirements of high-end products.

In application scenarios, the equipment demonstrates strong adaptability: it can be used for dispersing and mixing pigments/fillers with base materials in coating production, for uniform compounding of resins, curing agents and functional fillers in adhesives, and also for the preparation of precision electronic materials such as lithium battery slurries. Its high-efficiency mixing capability not only significantly shortens the production cycle but also ensures the consistency of material performance in each batch, providing stable support for large-scale, high-quality industrial production.

Features

Dual-planetary Agitation Motion: The mixing paddles perform both revolution (around the central axis of the mixing vessel) and rotation (around their own axes) simultaneously, mimicking the orbital motion of planets. This unique motion ensures comprehensive coverage of the entire vessel, eliminating mixing dead zones even in the corners and bottom.

Excellent Mixing for High-Viscosity Materials: It is specially designed to handle high-viscosity substances (typically up to several hundred thousand to over a million centipoise), such as adhesives, sealants, gels, and high-concentration pastes. The strong shear and kneading forces generated by the dual motion enable thorough blending of thick materials.

Versatile Paddle Options: Various types of mixing paddles (e.g., anchor paddles, dispersing discs, sigma blades) can be configured based on material properties and mixing requirements. This versatility allows it to adapt to different processes like mixing, dispersing, kneading, and degassing.

Optional Vacuum/Pressure Function: Many models are equipped with a vacuum system to remove air bubbles from the mixture, improving product density and quality. Some can also operate under positive pressure to handle volatile or special materials.

Easy Cleaning and Maintenance: The mixing vessel can often be tilted or lifted for convenient discharging of materials. Additionally, the design of detachable paddles and a smooth inner wall of the vessel facilitates thorough cleaning, meeting the hygiene standards of industries such as food, pharmaceuticals, and cosmetics.

Stable and Reliable Operation: The equipment adopts a rigid transmission structure and high-quality components, ensuring stable operation even under heavy-load mixing conditions. It also features multiple safety protections (e.g., overload protection, emergency stop) to guarantee operational safety.

Customizable Configurations: The capacity (from lab-scale small volumes to industrial large volumes), material of construction (stainless steel 304, 316L, etc.), and auxiliary systems (heating/cooling jackets, material feeding devices) can be customized according to specific production needs.

Application Areas

Double planetary mixers are widely used in many fields, as follows:

Daily chemical products: Used in the production of emulsions, creams, shampoos, shower gels, and other products that require fine texture and stable performance.

Biomedicine: Applied in the production of medical emulsions, ointments, oral liquids, and other preparations, meeting strict aseptic and fineness standards.

Food industry: Suitable for the production of emulsified foods such as yogurt, ice cream, cheese, and other products that require uniform mixing and stable quality.

Paint and ink: Used in the production of emulsified paints and inks, ensuring fine dispersion of components and stable product performance.

Nanomaterials: Applied in the preparation of nanomaterials, realizing efficient mixing and dispersion of nanoscale materials.

Petrochemical industry: Used in the production of emulsified petroleum products, improving product stability and usability.

Printing and dyeing auxiliaries: Suitable for the production of emulsified paper treatment agents and other printing and dyeing auxiliary products.

Pesticides and fertilizers: Used in the production of emulsified pesticides and fertilizers, enhancing the uniformity and effectiveness of products.

Plastic and rubber: Applied in the production of emulsified plastic and rubber materials, ensuring uniform distribution of additives.

Electric power and electronics industry: Used in the production of emulsified insulation materials and electronic components, meeting the industry's high-performance requirements.

Other fine chemical engineering fields: Such as the production of ceramic materials, glass processing auxiliaries, metal processing fluids, etc., providing reliable mixing solutions.

In short, double planetary mixers have a wide range of applications, mainly used to produce emulsified products and high-consistency materials. They play a key role in improving product stability, fineness, and overall performance in various industries.Gangben Mixer Manufacturer specializes in the research, development, production, and sales of mixing machines and filling machines. Its main products include vacuum emulsifying mixers, high-shear emulsifying mixers, vacuum homogenizing emulsifiers, filling and sealing machines, and liquid filling production lines. Equipped with modern production workshops and environments, we adopt advanced equipment manufacturing technologies and strict process quality management and control measures to ensure that all products are free from defects before leaving the factory.

Gangben Mixer Factory has obtained multiple patents for the research and development of emulsifying machines and planetary mixers, as well as ISO quality management system certification and international CE certification. Our products meet quality standards with a reliable quality guarantee. We are committed to manufacturing high-quality mixing machinery to enhance your production efficiency and reduce costs for your company.

English

English Russian

Russian French

French Spanish

Spanish Portuguese

Portuguese Korean

Korean Japanese

Japanese Thai

Thai