Liquid Filling Production Line

The Liquid Filling Production Line is a comprehensive system designed for efficient, high-volume production of liquid-filled containers. This integrated line combines various components and technologies to streamline the processes of liquid filling, capping, and packaging.

Always on time

Always on time Acceptable price

Acceptable price Excellent quality

Excellent quality

Description

Feature&Application

Factory Strength

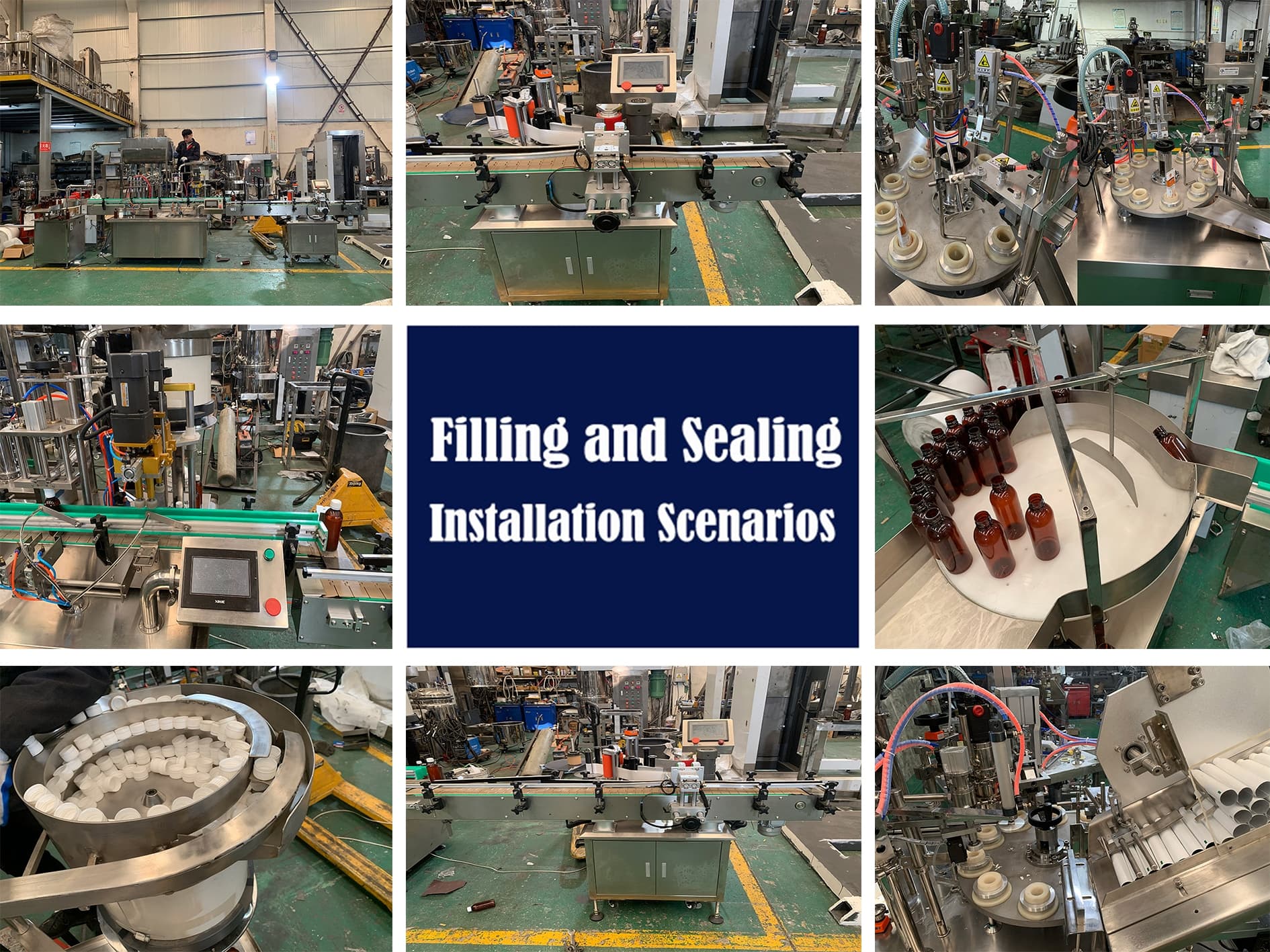

This model gathers mechanical, pneumatic, automatic as one unity. Great features such as high automatization and high yield, widely using, good stability make this model more popular.More functions: automatic bottle transit, automatic bottle detecting(No bottle, no filling) and filling, and automatic cap setting and capping. It's quite suitable for high error materials . Comparing with oversea products, this one is more competitive.

1. Components and Technologies

The Liquid Filling Production Line typically comprises a filling machine, capping machine, conveyor system, and quality control equipment—each component specifically engineered to address the unique challenges of liquid filling.

The filling machine employs a precision dosing system to accurately measure and dispense the required volume of liquid into each container. It generally includes a filling head with a pump that draws liquid from a reservoir and dispenses it into the container. The filling process is fully automated, minimizing the risk of human error and ensuring consistent fill volumes.

Once filled, the containers proceed to the capping machine, where they are sealed with a cap to create a tight seal. This prevents leakage and extends the product’s shelf life. The capping machine typically features a cap feeder mechanism that automatically selects and positions caps on the containers.

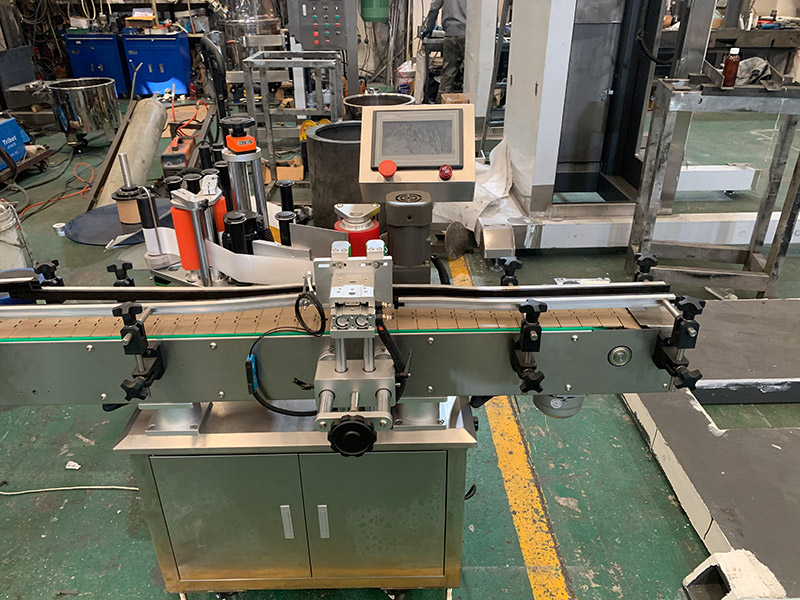

The conveyor system facilitates the movement of filled containers between stations within the production line. It ensures containers are precisely positioned for subsequent processes, such as quality control checks or labeling.

Quality control equipment is a critical component of the production line, inspecting various quality parameters including fill volume, cap tightness, and product purity. This equipment identifies potential issues early, ensuring only high-quality products are packaged and shipped.2. Efficiency and Flexibility

The Liquid Filling Production Line is engineered for efficient, flexible production. It accommodates a wide range of container sizes, shapes, and materials, making it suitable for diverse liquid products across multiple industries. The line’s automation and adaptability enable quick adjustments to production volume or product type, minimizing downtime and boosting overall efficiency.

3. Safety Considerations

Safety is a paramount feature of the Liquid Filling Production Line. It integrates safety mechanisms such as interlocks, protective guards, and emergency stop buttons to prevent operator injuries during operation. For environments handling flammable liquids, the line is also equipped with explosion-proof components, ensuring safe operation even in high-risk settings.

4. Environmental Considerations

Environmental sustainability is a core design principle of modern production lines, and the Liquid Filling Production Line aligns with this focus. It can be configured with energy-efficient components and low-noise operation to reduce energy consumption and minimize environmental impact. Additionally, optional waste reduction systems enable material recycling and reuse, further lowering its ecological footprint.

In conclusion, the Liquid Filling Production Line is a comprehensive system that integrates diverse components and technologies to efficiently produce high-quality liquid-filled containers. By offering flexibility, efficiency, robust safety features, and environmental sustainability, it proves to be an invaluable asset for any manufacturing facility requiring large-scale, cost-effective production of liquid-filled products.The filling and sealing machine is a type of highly automated packaging equipment with diverse mechanical types and technical advantages. It is widely used in product packaging across industries such as pharmaceuticals, food, cosmetics, and daily chemicals. Its primary function is to accurately inject various fluid materials—including pastes and liquids—into tubes or containers, and to complete operations such as sealing, printing batch numbers, and production dates.

The main functions, mechanical type classifications, technical advantages, and main application categories of the filling and sealing machine are as follows:I. Main Functions

The main function of the filling and sealing machine is to accurately inject various fluid materials, such as pastes and liquids, into tubes or containers, and to complete operations including sealing, printing batch numbers, and production dates. It is widely used in industries such as pharmaceuticals, food, cosmetics, and daily chemicals, with particular suitability for filling and sealing large-diameter plastic and composite tubes.

II. Mechanical Type Classification

Vertical filling and sealing machine: A widely used model suitable for filling and sealing various containers such as bottles, buckets, and cans of different specifications. It features high work efficiency, high precision, easy cleaning, and convenient maintenance.

Capping filling and sealing machine: Suitable for filling and sealing various bottled liquids, semi-liquids, and powders. It is characterized by simple operation, a high degree of automation, strong adaptability, and low cost.

Linear filling and sealing machine: Mainly used for filling and sealing products such as bottled liquids, semi-liquids, and powders. It boasts convenient operation, fast speed, and high accuracy.

III. Technical Advantages

Equipped with a PLC system and a button-operated LCD screen, the machine enables easy and intuitive operation. It features stepless speed adjustment, standard parameter settings, production count tracking, pressure index monitoring, and fault alerts.

The machine realizes fully automatic tube feeding, photoelectric registration, inert gas filling (optional), material filling and sealing, date coding, and final product discharge.

High-precision photoelectric registration minimizes color deviation.

External replaceable components are equipped with digital displays for convenient and accurate parameter adjustments, making it suitable for multi-product production.

Integrated control of mechanical, optoelectronic, electrical, and pneumatic systems enables functions such as "no tube, no filling" and "no tube, no water supply." It triggers an alarm if the tube is misaligned or pressure drops, and stops immediately when the protective door is opened.

After inflation, a blowing device removes excess material from the tube end.

It adopts the "no tube, no filling" principle to avoid material waste.

The inner part of the tube tail is heat-sealed using a Leister hot air generator, while external components are cooled by a dedicated cooling device.

Character codes are printed at optimal positions as required by the coding station.

A shaping manipulator shrinks the tube end to a selectable optimal angle or rounded shape.IV. Main Application Classification

Pharmaceutical industry: It is widely used in the pharmaceutical sector for filling and sealing medicinal products such as ointments, capsules, and tablets.

Food industry: It finds extensive application in the food sector for filling and sealing products like beverages, dairy products, and condiments.

Cosmetics industry: It is utilized for filling and sealing cosmetic items such as lotions, creams, and lipsticks.

Daily chemical industry: It is employed for filling and sealing daily chemical products including laundry detergent, hand sanitizer, and shower gel.

Other industries: Beyond the aforementioned sectors, filling and sealing machines can also be applied to product packaging in industries such as chemicals and pesticides.

In summary, the filling and sealing machine is a highly automated packaging equipment with diverse mechanical types and technical advantages, widely used in product packaging across industries such as pharmaceuticals, food, cosmetics, and daily chemicals.Gangben Mixer Manufacturer specializes in the research, development, production, and sales of mixing machines and filling machines. Its main products include vacuum emulsifying mixers, high-shear emulsifying mixers, vacuum homogenizing emulsifiers, filling and sealing machines, and liquid filling production lines. Equipped with modern production workshops and environments, we adopt advanced equipment manufacturing technologies and strict process quality management and control measures to ensure that all products are free from defects before leaving the factory.

Gangben Mixer Factory has obtained multiple patents for the research and development of emulsifying machines and planetary mixers, as well as ISO quality management system certification and international CE certification. Our products meet quality standards with a reliable quality guarantee. We are committed to manufacturing high-quality mixing machinery to enhance your production efficiency and reduce costs for your company.

-

PrevNone

-

NextNone

English

English Russian

Russian French

French Spanish

Spanish Portuguese

Portuguese Korean

Korean Japanese

Japanese Thai

Thai