The 50L Standard Material Press Machine

The 50L Standard Material Press Machine is a compact industrial/lab-grade device tailored for small-scale material compaction, dehydration, and sample preparation (e.g., small-batch sludge, pharmaceutical raw materials, food samples). Boasting a 50-liter effective working capacity, it features precise pressure control (0.6-1.0MPa), corrosion-resistant 304 stainless steel contact parts, and intuitive semi-automated operation. Ideal for labs, pilot plants, and small production lines, it delivers consistent performance, easy mobility, and low maintenance, meeting strict quality standards for small-batch processing.

Always on time

Always on time Acceptable price

Acceptable price Excellent quality

Excellent quality

Description

Feature&Application

Factory Strength

The 50L Standard Material Press Machine is engineered to fulfill the unique needs of small-scale material processing, bridging the gap between lab-scale tools and large industrial presses. Its 50-liter effective working chamber is specifically optimized for handling small-batch materials—including municipal sludge samples, pharmaceutical powders, food processing by-products, and chemical intermediates—making it an indispensable asset for research laboratories, pilot production lines, and small-to-medium enterprises (SMEs) with low-volume processing demands.

Performance-wise, the machine prioritizes precision and consistency, critical for small-batch applications. It operates within a controlled pressure range of 0.6-1.0MPa, adjustable via a built-in control panel to suit different material properties (e.g., delicate powders vs. dense sludge). This precision ensures reliable dehydration (reducing moisture content by 25-40% based on material type) without compromising sample integrity—a key requirement for lab testing or pilot-scale product development. All material-contact components are crafted from 304 stainless steel, offering excellent resistance to corrosive substances and complying with food and pharmaceutical industry hygiene standards, ensuring product safety and equipment longevity.

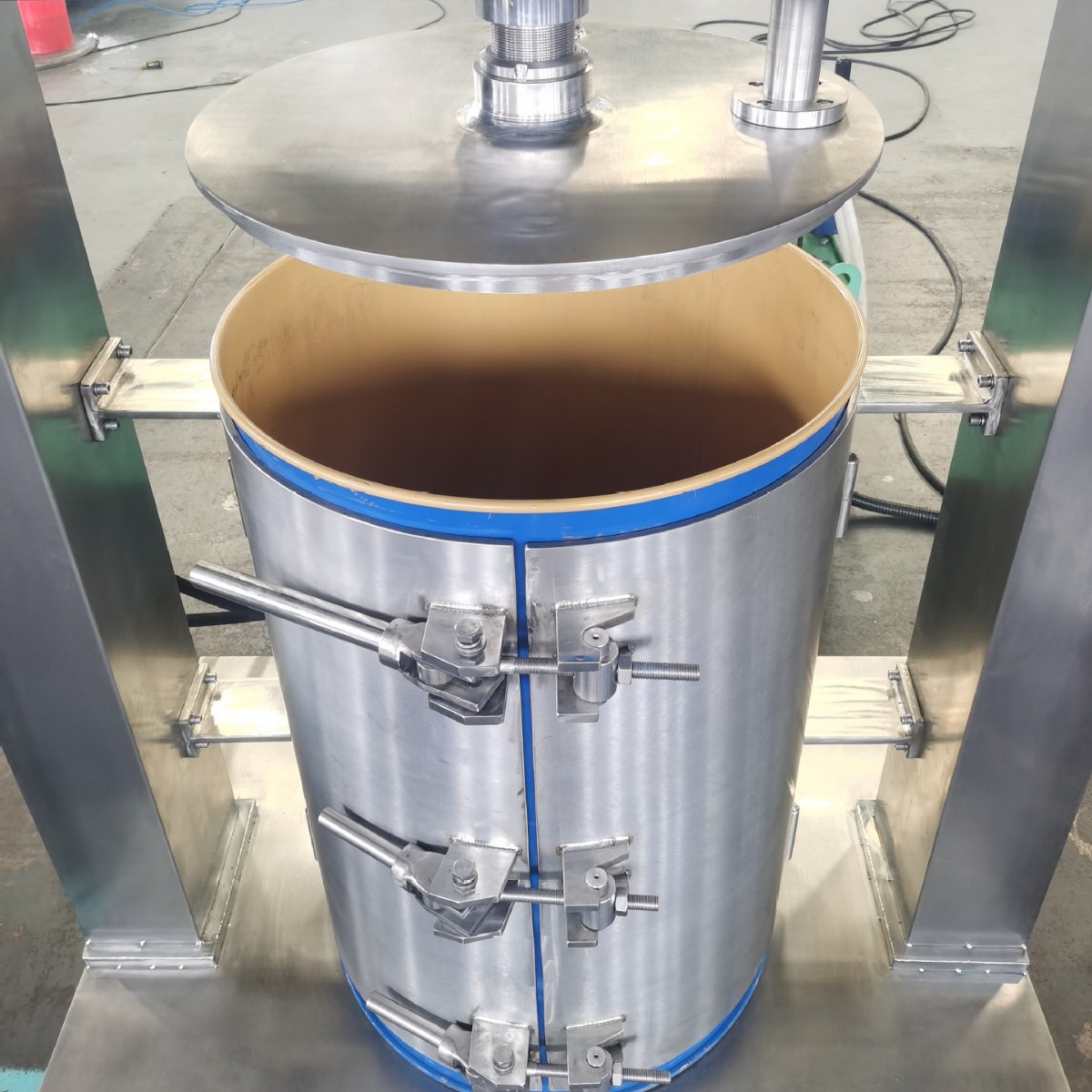

Design-wise, compactness and usability are core strengths. With a space-saving footprint (typically 1200×800×1500mm, subject to configuration) and optional mobility casters, the machine can be easily positioned in labs or crowded production areas. Its semi-automated operation—equipped with a digital display for pressure/timer monitoring and one-touch start/stop functions—simplifies use, even for operators with basic training. Safety is also integrated, including overpressure protection, thermal overload safeguards, and a safety interlock on the chamber door to prevent accidents during operation.

Maintenance and adaptability further enhance its value. The machine’s streamlined modular design allows quick access to key components (e.g., hydraulic cylinders, filters) for routine maintenance, minimizing downtime. It also supports optional attachments, such as custom-sized molds for shaped sample preparation or additional sensors for data logging—critical for lab research requiring process traceability. Compared to larger presses, it consumes 30-40% less energy, aligning with the low-power needs of small-scale operations and reducing operational costs.

In summary, the 50L Standard Material Press Machine combines compact design, precise performance, and versatility, making it a cost-effective, reliable solution for businesses and labs seeking high-quality small-batch material processing.

Features

The 50L Standard Material Press Machine is a versatile industrial device designed for efficient solid-liquid separation and material compression, with features tailored to small-to-medium batch processing needs. A core feature is its optimized 50L capacity and high efficiency (pressing efficiency). The 50L processing chamber strikes a balance between compact size and practical output, ideal for businesses requiring 30–45L of processed material per batch—avoiding the inefficiency of oversized presses for small loads or repeated runs of mini presses. Equipped with a hydraulic or pneumatic pressing system (depending on the model), it delivers consistent pressure (typically 0.8–1.2 MPa) to extract liquids from solids or compress bulk materials, achieving a liquid recovery rate of 85–95% for most fibrous or granular materials—significantly higher than manual pressing or low-capacity alternatives.

Another standout feature is its standardized, user-friendly design. Built to industry-wide standards, it features a simple control panel with adjustable pressure and pressing time settings, allowing operators to fine-tune parameters for different materials (e.g., softer fruits vs. dense herbs). The 50L chamber is made of food-grade 304 stainless steel (or 316 for corrosive materials), ensuring compliance with hygiene and safety regulations while resisting wear from abrasive materials. Additionally, the machine’s detachable filter screen (usually 80–120 mesh) and easy-to-open chamber lid simplify cleaning and maintenance—reducing downtime between batches, a key advantage for continuous small-batch production.

It also boasts stable performance and safety. The base is reinforced with a heavy-duty steel frame to prevent tipping during high-pressure operation, while safety features like pressure overload protection and emergency stop buttons minimize accident risks. Unlike custom-built presses that may require specialized maintenance, its standardized components (e.g., hydraulic cylinders, valves) are readily available in the market, lowering repair costs and ensuring long-term reliability. This combination of efficiency, usability, and durability makes it a cost-effective choice for small-to-medium enterprises.

Application Areas

The 50L Standard Material Press Machine finds wide application in industries where small-batch, high-quality solid-liquid separation or material compression is critical. In the food and beverage industry, it is a staple for processing fruits, vegetables, and herbs. For small-scale juice producers, it efficiently extracts juice from apples, grapes, or berries—its 50L capacity matches the output needs of local juice bars or artisanal producers, while the high pressing efficiency ensures maximum juice yield without compromising flavor (since gentle, controlled pressure avoids crushing seeds or releasing bitter compounds). It is also used to press olive oil for small-batch artisanal production or to extract liquids from fermented foods like kimchi or sauerkraut, aiding in flavor concentration.

In the pharmaceutical and herbal processing sector, it plays a key role in extracting active ingredients from medicinal plants. For example, it presses dried herbs (e.g., mint, lavender, ginseng) to extract essential oils or liquid extracts used in herbal supplements, tinctures, or topical medications. The 50L capacity is ideal for small pharmaceutical labs or herbal remedy manufacturers, allowing precise batch control to ensure consistent ingredient concentration. The stainless steel chamber’s hygiene compliance prevents cross-contamination, a critical requirement for pharmaceutical-grade products.

The chemical and environmental industries also benefit from this machine. It is used to dewater industrial sludge (e.g., from wastewater treatment plants) or press wet chemical residues—reducing the volume of waste for easier disposal or recycling. For small chemical facilities, the 50L capacity handles sludge batches generated daily, while the adjustable pressure settings accommodate different sludge consistencies. It also aids in extracting liquids from natural resins (e.g., pine resin) used in adhesives or coatings, ensuring pure, high-quality extracts.

Additionally, in the agricultural sector, it is used to press animal feed (e.g., pressing wet forage into compact pellets) or extract liquids from agricultural by-products (e.g., pressing sugarcane bagasse to recover residual sugar syrup). This versatility across food, pharmaceutical, chemical, and agricultural industries solidifies its role as a essential tool for small-to-medium batch material processing.

Gangben Mixer Manufacturer specializes in the research, development, production, and sales of mixing machines and filling machines. Its main products include vacuum emulsifying mixers, high-shear emulsifying mixers, vacuum homogenizing emulsifiers, filling and sealing machines, and liquid filling production lines. Equipped with modern production workshops and environments, we adopt advanced equipment manufacturing technologies and strict process quality management and control measures to ensure that all products are free from defects before leaving the factory.

Gangben Mixer Factory has obtained multiple patents for the research and development of emulsifying machines and planetary mixers, as well as ISO quality management system certification and international CE certification. Our products meet quality standards with a reliable quality guarantee. We are committed to manufacturing high-quality mixing machinery to enhance your production efficiency and reduce costs for your company.

English

English Russian

Russian French

French Spanish

Spanish Portuguese

Portuguese Korean

Korean Japanese

Japanese Thai

Thai