100L Planetary Disperser Mixer

The 100L Planetary Disperser Mixer is an industrial-grade mixing equipment integrating planetary stirring and high-speed dispersion. Ideal for medium-to-large batch production and pilot scaling, it features precise temp control (RT-100℃), adjustable speed (0-2000rpm), and 304/316 stainless steel construction. It efficiently handles coatings, adhesives, and composites, delivering stable, homogeneous mixing for industrial workflows.

Always on time

Always on time Acceptable price

Acceptable price Excellent quality

Excellent quality

Description

Feature&Application

Factory Strength

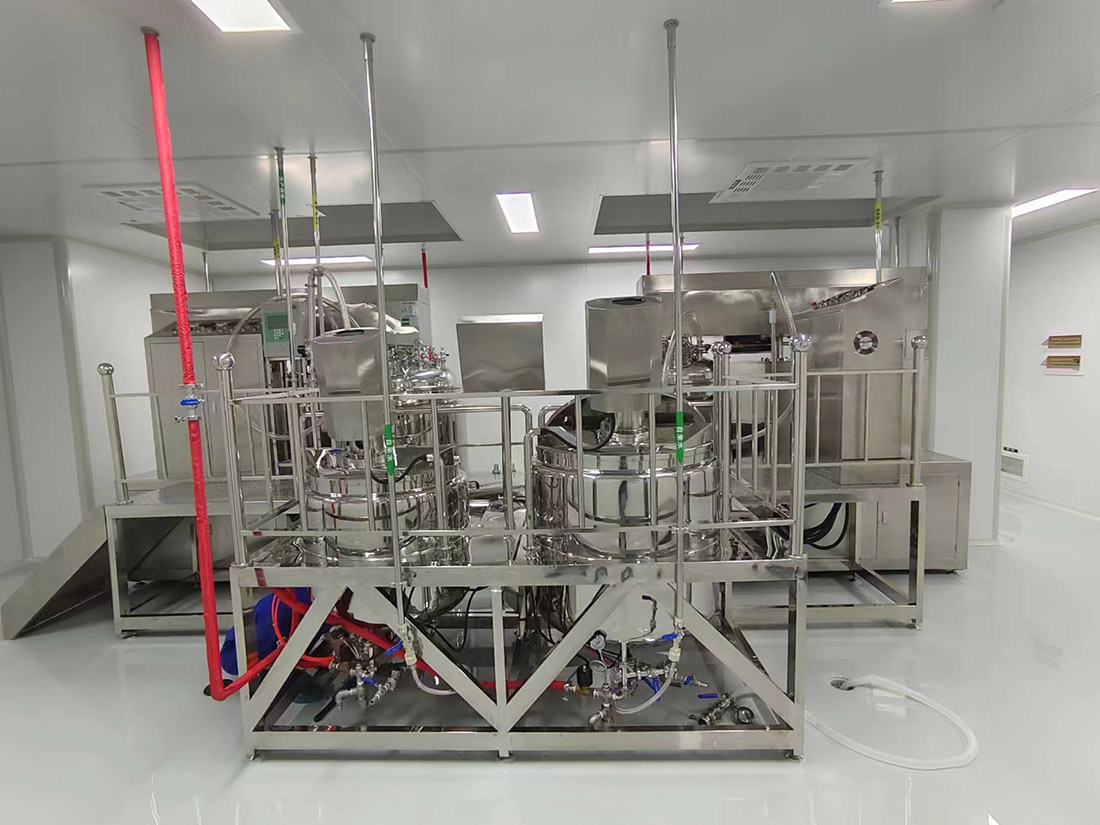

The 100L Planetary Disperser Mixer is a heavy-duty industrial mixing solution engineered to meet the demands of medium-to-large batch production, pilot-scale scaling, and high-volume R&D across key sectors including coatings, adhesives, composite materials, pharmaceuticals, and specialty chemicals. By synergizing planetary rotation (for uniform bulk blending) and high-speed dispersion (for fine particle size reduction), it achieves exceptional homogeneity even for high-viscosity, multi-component materials—eliminating agglomeration and ensuring consistent product quality in every run.

With a 100L working capacity, this mixer serves as a critical link between small-batch trials and full-scale manufacturing, enabling businesses to validate formulations at production-relevant volumes before scaling up, thus reducing risks and optimizing time-to-market. It is equipped with advanced precision controls: temperature regulation from room temperature to 100℃ adapts to heat-sensitive ingredients and thermally driven processes, while the 0-2000rpm stepless adjustable speed range caters to diverse material properties, from thin resins to thick pastes.

Constructed with food-grade 304 stainless steel (or optional 316L for stricter hygiene needs), the mixing chamber, agitators, and contact parts offer superior corrosion resistance against harsh solvents, acids, and abrasives—ensuring material purity and a long service life. The intuitive touch-screen control panel provides real-time monitoring of temperature, speed, mixing time, and torque, supporting precise process replication and compliance with industrial quality standards.

Designed for operational efficiency, it features a tiltable mixing chamber and quick-release agitators for easy cleaning and material discharge, minimizing downtime between batches. Safety is prioritized with overload protection, emergency stop buttons, and a safety interlock system, ensuring compliance with global industrial safety regulations.

Whether producing large batches of industrial coatings, structural adhesives, or composite slurries, the 100L Planetary Disperser Mixer delivers reliable, high-performance mixing that streamlines production workflows and reduces operational costs—making it a strategic investment for businesses aiming to enhance scalability and competitiveness.The technical features and application industries of the double planetary mixer are as follows:

Technical Features:

Broad application range: The double planetary mixer is suitable for diverse processes, including the dissolution, mixing, blending, and reaction of materials ranging from powders to high-viscosity and high-density substances.

High mixing efficiency: By employing the double planetary mixing principle, the mixer achieves efficient, uniform mixing, thereby boosting production efficiency and enhancing product quality.

User-friendly and safe operation: The mixer supports automatic control, featuring simple, stable, fast, and convenient operation to ensure safe equipment operation.

No mixing dead zones, no material climbing, and superior sealing: The mixer’s blades perform planetary motion (revolving around the central axis) while rotating on their own axes, ensuring thorough mixing without dead zones. Its design also prevents material climbing and ensures excellent sealing performance.

Precise temperature measurement and rapid heating/cooling: Equipped with both low-speed mixing components and high-speed dispersing components:The low-speed mixing components utilize planetary gear transmission; their blades rotate on their own axes while performing planetary motion, achieving optimal mixing results in a short time.The high-speed dispersing components rotate at high speed on their own axes while revolving with the planetary carrier, subjecting materials to intense shearing and dispersive mixing—delivering mixing effects several times more efficient than ordinary mixers.

Application Industries:

Aerospace polymer materials: Applied in the preparation of high-performance composite materials, coatings, and related products.

Battery paste: Utilized for the preparation and mixing of battery electrode slurries.

Food industry: Employed in the mixing and seasoning of food ingredients.

Chemical industry: Used for the dissolution, mixing, and reaction of chemical raw materials.Pharmaceutical industry: Applied to the mixing and preparation of pharmaceutical raw materials.

Pharmaceutical industry: Applied to the mixing and preparation of pharmaceutical raw materials.

In summary, the double planetary mixer is an efficient, versatile mixing and stirring device, suitable for processes such as material dissolution, mixing, blending, and reaction across a wide range of industries.

Gangben Mixer Manufacturer specializes in the research, development, production, and sales of mixing machines and filling machines. Its main products include vacuum emulsifying mixers, high-shear emulsifying mixers, vacuum homogenizing emulsifiers, filling and sealing machines, and liquid filling production lines. Equipped with modern production workshops and environments, we adopt advanced equipment manufacturing technologies and strict process quality management and control measures to ensure that all products are free from defects before leaving the factory.

Gangben Mixer Factory has obtained multiple patents for the research and development of emulsifying machines and planetary mixers, as well as ISO quality management system certification and international CE certification. Our products meet quality standards with a reliable quality guarantee. We are committed to manufacturing high-quality mixing machinery to enhance your production efficiency and reduce costs for your company.

Recommend Products

Recommend Faq

-

Sep 04,2025

Sep 04,2025Lab Emulsifier Mixer Buying Guide: 5 Key Parameters for Optimal Homogenization Performance

-

Sep 04,2025

Sep 04,2025Vacuum Emulsifying Homogenizer: How to Achieve Nano-Scale Dispersion for High-Viscosity Materials?

-

Aug 27,2025

Aug 27,20252025 Emulsifying Homogenizer Market Report: Trends, Growth Drivers & Competitive Landscape

English

English Russian

Russian French

French Spanish

Spanish Portuguese

Portuguese Korean

Korean Japanese

Japanese Thai

Thai