Lab Emulsifier Mixer Buying Guide: 5 Key Parameters for Optimal Homogenization Performance

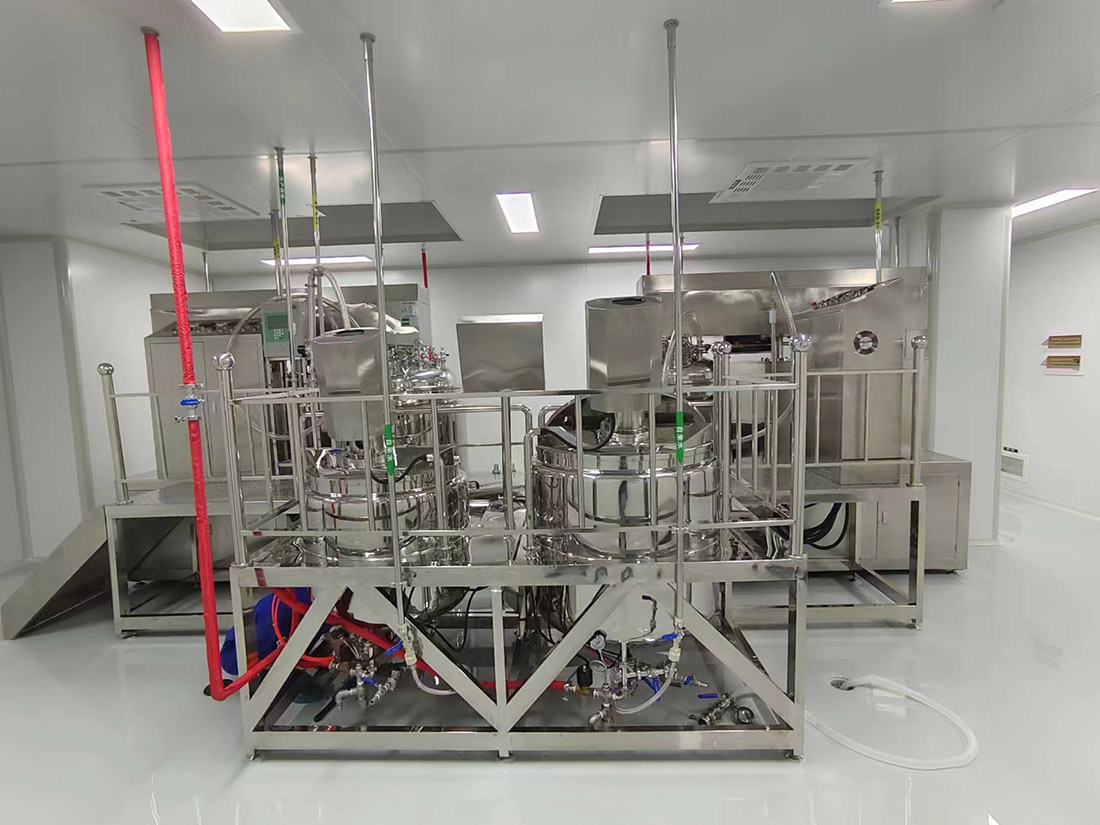

In laboratory settings, lab emulsifier mixers are indispensable for achieving nano-scale dispersion in industries such as cosmetics, pharmaceuticals, food, and chemicals. Their performance directly impacts product stability, particle size distribution, and production efficiency. This guide outlines five critical parameters for selecting an optimal lab emulsifier mixer, incorporating insights from Jiangsu GangBen Mixer Manufacturer, a leader in vacuum emulsification technology.

1.Capacity and Batch Scalability: From Lab to Pilot-Scale Precision

The mixer’s capacity must align with research objectives. For instance, Jiangsu GangBen’s 10L vacuum emulsifier mixer is ideal for small-batch formulation validation, while its 50L model supports pilot-scale production. The company’s product range spans 5L to 500L, enabling seamless scaling from concept verification to industrial manufacturing.

Key Considerations:

Prioritize modular designs for easy upgrades during R&D progression.

Jiangsu GangBen’s JT-50 (50L) model, crafted from 304/316L stainless steel, achieves D90 particle sizes ≤800nm for high-viscosity materials (e.g., 5000mPa·s silicone oil).

2. Shear Rate and Power: The Core of Nano-Scale Dispersion

Shear rate (RPM) and power (kW) determine dispersion efficiency. Jiangsu GangBen’s lab mixers feature multi-stage stator-rotor systems that generate ultra-high shear forces (0-30,000 RPM) within 0.1–1mm gaps, enabling:

Low-viscosity materials (e.g., oil-in-water emulsions): Wide-gap modules enhance turbulence.

High-viscosity materials (e.g., toothpaste, nano-conductive pastes): Narrow-gap modules ensure shear penetration.

Case Study: A global cosmetics group used Jiangsu GangBen’s 1000L production line to disperse sunscreen agents to an average particle size of 220nm, boosting light transmittance to 97% and enhancing UV protection.

3.Vacuum System: Eliminating Bubbles for Superior Stability

Vacuum environments prevent oxidation and instability caused by air incorporation while facilitating precise material transfer. Jiangsu GangBen’s lab mixers integrate independent vacuum pumps with pressures down to -0.098MPa, achieving:

Degassing: Removes adsorbed gases from nanomaterials to prevent post-dispersion agglomeration.

Material transfer: Negative pressure ensures residue-free feeding of raw materials.

Sealing: Prevents volatilization of active ingredients during processing.

Data Insight: In nano-graphene dispersion trials, vacuum conditions increased concentration from 0.5mg/mL to 2.8mg/mL with no sedimentation over six months.

4. Temperature Control: Precision for Process Optimization

Temperature influences material viscosity and nanomaterial surface activity. Jiangsu GangBen’s lab mixers incorporate electric/steam heating systems with ±1°C accuracy, supporting:

Low-temperature dispersion (40–60°C): Reduces viscosity of high-viscosity materials for improved flowability.

High-temperature modification (80–120°C): Promotes surface reactions of nanomaterials to enhance dispersion stability.

Application Example: A pharmaceutical enterprise improved drug release rates by 40% in nano-drug creams using temperature-controlled processes.

5. Material Quality and Safety: Durability for Long-Term Use

Lab mixers must withstand corrosive chemicals, organic solvents, and frequent cleaning. Jiangsu GangBen’s devices use SUS316L stainless steel, offering:

Corrosion resistance: Compliant with GMP standards to prevent metal ion contamination.

Easy cleaning: Mirror-polished surfaces (Ra≤0.4μm) minimize residue buildup.

Safety: Equipped with overload protection, leak detection, and emergency stop buttons (CE-certified).

User Feedback: A food company reported zero corrosion or leakage over three years of continuous operation, reducing maintenance costs by 40%.

Jiangsu GangBen Mixer Manufacturer: Pioneering Lab Emulsifier Technology

As a leader in vacuum emulsification equipment, Jiangsu GangBen delivers:

Customization: Tailored solutions from 5L to 500L for diverse R&D needs.

Process expertise: Access to a database of 1,000+ formulation parameters for free technical consultation.

Global support: Products exported to 30+ countries with 24/7 remote diagnostics.

Selecting a lab emulsifier mixer requires balancing capacity, shear performance, vacuum capabilities, temperature control, and material safety. Jiangsu GangBen Mixer Manufacturer’s modular designs, multi-stage shear technology, and (intelligent) control systems provide end-to-end solutions for global clients. As nanotechnology advances, their equipment will continue t

News

- Latest News

- Solutions

- FAQ

Recommend Products

-

5L Vacuum Emulsifying Homogenizer Mixer

5L Vacuum Emulsifying Homogenizer MixerThe 5L vacuum emulsifying mixer is a device designed for emulsifying and mixing various substances in a vacuum environment. This equipment is equipped with a mixing tank with a capacity of 5 liters and is widely applied in industries such as food, pharmaceuticals, cosmetics, and pesticides.

-

5L PLC-Screen Vacuum Emulsifying Mixer

5L PLC-Screen Vacuum Emulsifying MixerThe 5L PLC-Screen Vacuum Emulsifying Mixer is a device designed for emulsifying and mixing various substances in a vacuum environment. This equipment is equipped with a mixing tank with a capacity of 5 liters and is widely applied in industries such as food, pharmaceuticals, cosmetics, and pesticides.

-

10L Vacuum Emulsifying Homogenizer Mixer

10L Vacuum Emulsifying Homogenizer MixerThe 10L Vacuum Emulsifying Mixer is a device used for emulsifying and mixing various substances in a vacuum environment. It is commonly used in industries such as food, cosmetics, and pharmaceuticals.

Recommend Faq

-

Jan 28,2026

Jan 28,2026Vacuum Degree, Material, and Homogenizing Head: 5 Major Misunderstandings to Avoid When Selecting a Model

-

Jan 28,2026

Jan 28,2026GMP Certification vs. Ordinary Models: A Deep Analysis of the Core Differences of Medical Grade Vacuum Emulsification Machines

-

Jan 13,2026

Jan 13,2026From Lab to Industrial Scale: How Jiangsu GangBen’s Vacuum Emulsifiers Redefine Production Standards Across Industries

English

English Russian

Russian French

French Spanish

Spanish Portuguese

Portuguese Korean

Korean Japanese

Japanese Thai

Thai