10L Double Planetary Mixer with Press Feeder

The 10L Double Planetary Mixer with Press Feeder is a versatile mixing solution tailored for medium-small batch production and pilot-scale R&D. Its dual planetary agitators execute simultaneous and revolution, guaranteeing homogeneous mixing of high-viscosity materials up to 1,500,000 cP. The integrated pneumatic press feeder prevents material bridging and enables continuous, stable feeding, enhancing workflow efficiency. Constructed with 304/316L stainless steel contact parts, it complies with FDA and GMP standards, suitable for food, pharmaceutical, and chemical industries. Featuring a digital control panel and multiple safety safeguards, it balances operational simplicity with reliability, ideal for adhesives, sealants, composites, and cosmetic formulations.

Always on time

Always on time Acceptable price

Acceptable price Excellent quality

Excellent quality

Description

Feature&Application

Factory Strength

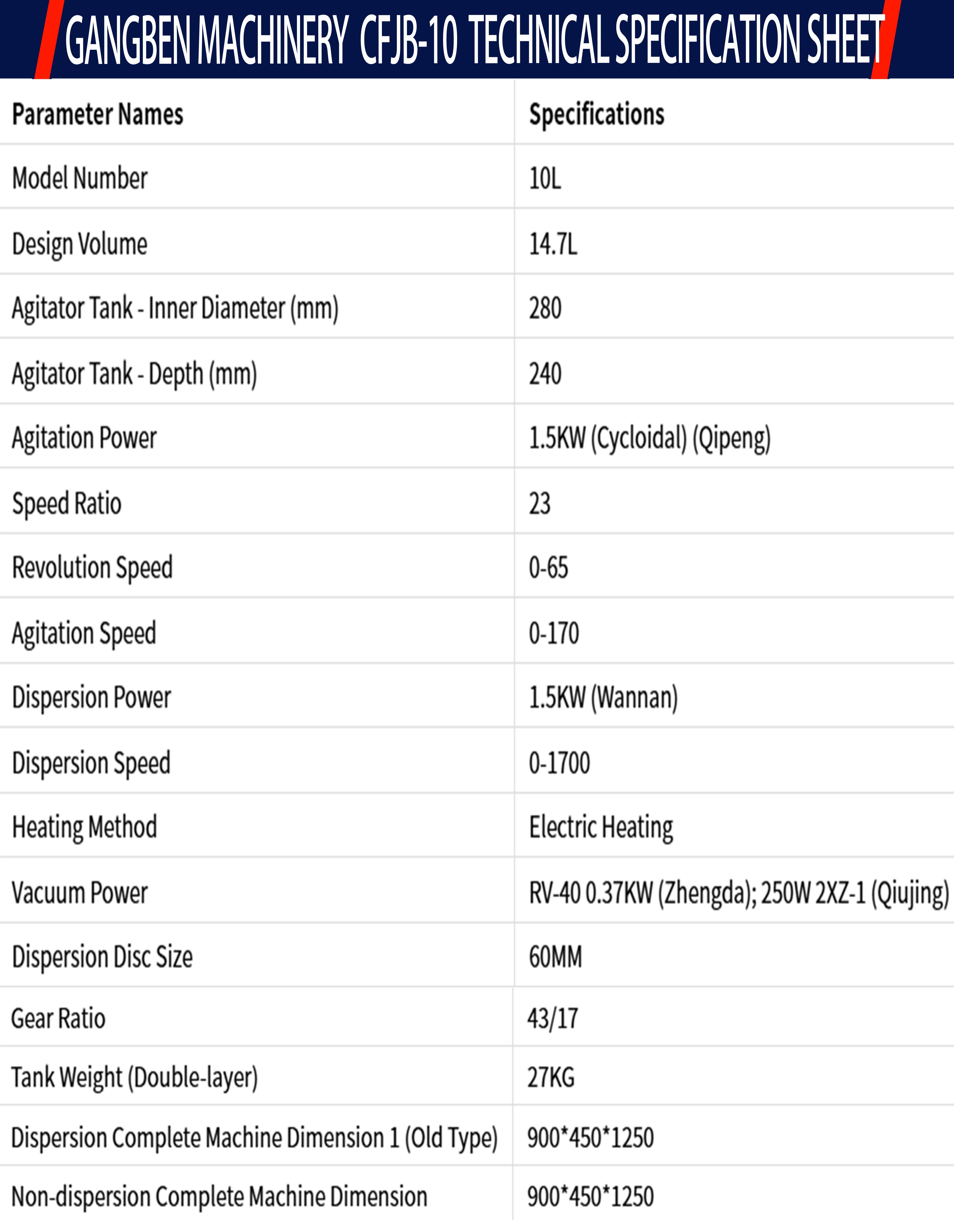

The 10L Double Planetary Mixer with Press Feeder is engineered to deliver precise, efficient mixing for medium-small batch production, pilot trials, and R&D across diverse industrial sectors. Its core lies in the dual planetary agitator system: two synchronized stirrers rotate independently at adjustable speeds (0-170 rpm) while orbiting the 10L stainless steel mixing tank. This dual-motion design generates powerful shear, kneading, and folding forces, ensuring thorough homogenization of high-viscosity materials—from adhesives and epoxy resins to silicone rubbers, pastes, and composite slurries—eliminating dead zones and inconsistent mixing that plague conventional mixers.

Seamlessly integrated with the mixer, the pneumatic press feeder automates material feeding, addressing the challenge of viscous material handling. With adjustable pressure (》0.096MPa), it adapts to varying material viscosities, preventing bridging, clumping, and uneven flow, thus reducing manual intervention and ensuring a continuous supply to the mixing tank. The tank, agitators, and feeder contact surfaces are crafted from 304 or optional 316L stainless steel, offering excellent corrosion resistance, easy cleaning, and compliance with FDA and GMP regulations, making it suitable for sensitive applications like pharmaceutical ointments and food additives.

Designed for user-centric operation, the mixer is equipped with a digital touchscreen control panel, allowing precise adjustment of speed, mixing time, and feeder pressure. It can store up to 15 custom programs, enabling quick recall for recurring processes. Safety is paramount: it features emergency stop buttons, tank cover interlocks, overload protection, and thermal safeguards to minimize operational risks. The compact footprint (approx. 900*450*1250 mm) saves workshop space, while the heavy-duty movable base with locking casters ensures easy relocation and stable operation.

This mixer excels in scenarios such as adhesive manufacturers’ pilot production, pharmaceutical firms’ formulation development, and composite labs’ material testing. It simplifies scaling from lab recipes to commercial production, reduces material waste by up to 15%, and shortens processing cycles. Backed by a 12-month warranty, global after-sales support, and optional accessories like vacuum systems or heating/cooling jackets, the 10L Double Planetary Mixer with Press Feeder combines durability, versatility, and performance to meet the evolving needs of modern medium-small batch mixing applications.

Features

Dual-planetary Agitation Motion: The mixing paddles perform both revolution (around the central axis of the mixing vessel) and rotation (around their own axes) simultaneously, mimicking the orbital motion of planets. This unique motion ensures comprehensive coverage of the entire vessel, eliminating mixing dead zones even in the corners and bottom.

Excellent Mixing for High-Viscosity Materials: It is specially designed to handle high-viscosity substances (typically up to several hundred thousand to over a million centipoise), such as adhesives, sealants, gels, and high-concentration pastes. The strong shear and kneading forces generated by the dual motion enable thorough blending of thick materials.

Versatile Paddle Options: Various types of mixing paddles (e.g., anchor paddles, dispersing discs, sigma blades) can be configured based on material properties and mixing requirements. This versatility allows it to adapt to different processes like mixing, dispersing, kneading, and degassing.

Optional Vacuum/Pressure Function: Many models are equipped with a vacuum system to remove air bubbles from the mixture, improving product density and quality. Some can also operate under positive pressure to handle volatile or special materials.

Easy Cleaning and Maintenance: The mixing vessel can often be tilted or lifted for convenient discharging of materials. Additionally, the design of detachable paddles and a smooth inner wall of the vessel facilitates thorough cleaning, meeting the hygiene standards of industries such as food, pharmaceuticals, and cosmetics.

Stable and Reliable Operation: The equipment adopts a rigid transmission structure and high-quality components, ensuring stable operation even under heavy-load mixing conditions. It also features multiple safety protections (e.g., overload protection, emergency stop) to guarantee operational safety.

Customizable Configurations: The capacity (from lab-scale small volumes to industrial large volumes), material of construction (stainless steel 304, 316L, etc.), and auxiliary systems (heating/cooling jackets, material feeding devices) can be customized according to specific production needs.

Application Areas

Double planetary mixers are widely used in many fields, as follows:

Daily chemical products: Used in the production of emulsions, creams, shampoos, shower gels, and other products that require fine texture and stable performance.

Biomedicine: Applied in the production of medical emulsions, ointments, oral liquids, and other preparations, meeting strict aseptic and fineness standards.

Food industry: Suitable for the production of emulsified foods such as yogurt, ice cream, cheese, and other products that require uniform mixing and stable quality.

Paint and ink: Used in the production of emulsified paints and inks, ensuring fine dispersion of components and stable product performance.

Nanomaterials: Applied in the preparation of nanomaterials, realizing efficient mixing and dispersion of nanoscale materials.

Petrochemical industry: Used in the production of emulsified petroleum products, improving product stability and usability.

Printing and dyeing auxiliaries: Suitable for the production of emulsified paper treatment agents and other printing and dyeing auxiliary products.

Pesticides and fertilizers: Used in the production of emulsified pesticides and fertilizers, enhancing the uniformity and effectiveness of products.

Plastic and rubber: Applied in the production of emulsified plastic and rubber materials, ensuring uniform distribution of additives.

Electric power and electronics industry: Used in the production of emulsified insulation materials and electronic components, meeting the industry's high-performance requirements.

Other fine chemical engineering fields: Such as the production of ceramic materials, glass processing auxiliaries, metal processing fluids, etc., providing reliable mixing solutions.

In short, double planetary mixers have a wide range of applications, mainly used to produce emulsified products and high-consistency materials. They play a key role in improving product stability, fineness, and overall performance in various industries.Gangben Mixer Manufacturer specializes in the research, development, production, and sales of mixing machines and filling machines. Its main products include vacuum emulsifying mixers, high-shear emulsifying mixers, vacuum homogenizing emulsifiers, filling and sealing machines, and liquid filling production lines. Equipped with modern production workshops and environments, we adopt advanced equipment manufacturing technologies and strict process quality management and control measures to ensure that all products are free from defects before leaving the factory.

Gangben Mixer Factory has obtained multiple patents for the research and development of emulsifying machines and planetary mixers, as well as ISO quality management system certification and international CE certification. Our products meet quality standards with a reliable quality guarantee. We are committed to manufacturing high-quality mixing machinery to enhance your production efficiency and reduce costs for your company.

English

English Russian

Russian French

French Spanish

Spanish Portuguese

Portuguese Korean

Korean Japanese

Japanese Thai

Thai