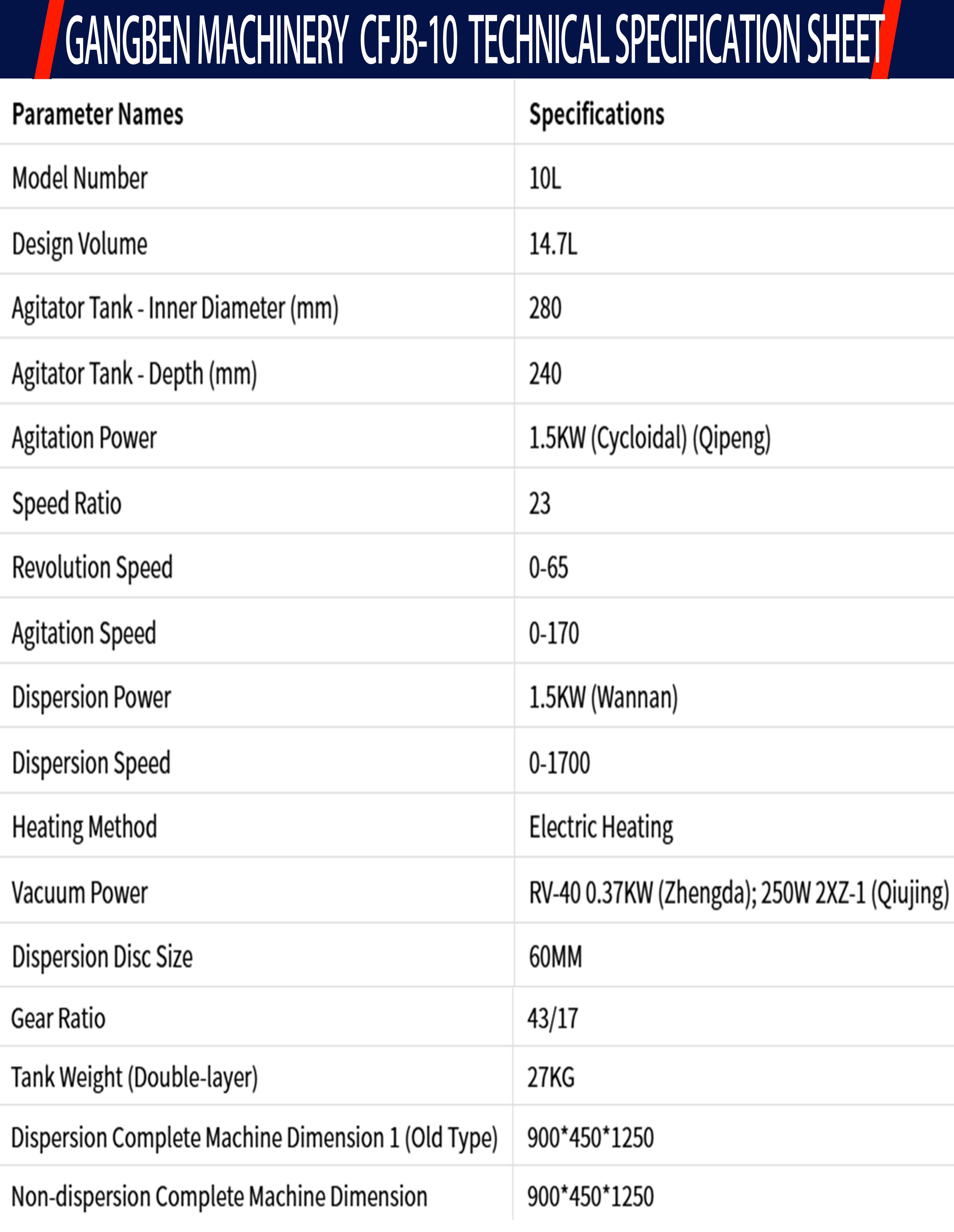

10L Vacuum Mixer

This 10L vacuum mixer is an ideal choice for high-efficiency blending, designed specifically for small to medium-batch production. It operates in a vacuum environment to prevent material oxidation and foaming, ensuring uniform mixing and product quality. Equipped with a powerful motor and precise speed control system, it adapts to various materials such as liquids, powders, and pastes, widely used in food, cosmetics, pharmaceutical and other industries. The stainless steel chamber is easy to clean, and the operation is user-friendly, combining high efficiency with practicality to provide a reliable solution for diverse blending needs.

Always on time

Always on time Acceptable price

Acceptable price Excellent quality

Excellent quality

Description

Feature&Application

Factory Strength

10L Vacuum Mixer: High-Efficiency Blending Solution is a professional mixing equipment that integrates precise craftsmanship and practical design. With its 10L optimal capacity, it caters to small to medium-batch production scenarios, delivering efficient solutions for blending needs across multiple industries.

The core advantage of the equipment lies in its vacuum operation technology. By extracting air from the chamber to create a negative pressure environment, it fundamentally reduces oxidation reactions and foam generation during material mixing. This makes it particularly suitable for products with strict requirements on color, purity, and fineness, such as cosmetic emulsions, pharmaceutical ointments, and high-end food fillings. It is paired with a powerful yet quiet motor that delivers stable output with low energy consumption. Combined with multi-gear precise speed regulation, it can flexibly adjust the mixing speed according to material viscosity—from thin liquids to highly viscous pastes—ensuring uniform mixing of materials with different properties and avoiding problems like local agglomeration or uneven blending.

The body is made of 304 food-grade stainless steel, featuring a smooth, dead-angle-free chamber. This not only provides corrosion resistance and easy cleaning but also ensures the safety of material contact, complying with the hygiene standards of the food and pharmaceutical industries. Humanized design is reflected in every detail: a transparent observation window allows real-time monitoring of the mixing status; a one-button control panel reduces the learning curve; detachable mixing components simplify cleaning and maintenance. Additionally, it is equipped with safety devices such as overheating protection and leakage protection to fully ensure operational safety.

From small-batch laboratory R&D to mass production in small and medium-sized enterprises, this 10L vacuum mixer has become a practical mixing equipment across cosmetics, pharmaceuticals, food and other fields, thanks to its comprehensive characteristics of "efficient blending, quality assurance, easy operation, and safe durability". It helps users improve production efficiency and product quality.

Features

Vacuum mixers stand out in mixing equipment due to unique traits tailored for high-quality material processing. A primary feature is air bubble elimination. Unlike conventional mixers that trap air during agitation—causing defects like surface blemishes in coatings or weakened structures in composites—vacuum mixers create a low-pressure chamber. This environment extracts air before and during mixing, ensuring mixtures remain dense and bubble-free, critical for products demanding structural integrity.

Another key trait is superior mixing uniformity. Equipped with specialized agitators (e.g., dual planetary blades), they generate strong shear forces and 360° material circulation. This addresses a common issue with standard mixers: uneven blending of high and low-viscosity materials (e.g., thick resins with thin additives). The vacuum environment further enhances uniformity by preventing air pockets that disrupt ingredient distribution, guaranteeing consistent product quality batch after batch.

They also offer versatility for high-viscosity materials. Many industries handle thick substances like adhesives, silicone rubbers, or pastes—materials that conventional mixers struggle to agitate. Vacuum mixers’ robust motor systems and custom agitator designs efficiently blend these viscous materials without compromising texture or consistency. Additionally, most models have adjustable vacuum levels and mixing speeds, allowing customization for diverse materials, from delicate pharmaceuticals to heavy-duty industrial compounds. This flexibility makes them indispensable for processes requiring precise control over mixing conditions.

Application Areas

Vacuum mixers find wide use across industries where mixing quality directly impacts product performance. The electronics industry relies on them to produce semiconductor encapsulants and printed circuit board (PCB) adhesives. These applications demand bubble-free mixtures—air bubbles in encapsulants can cause electrical shorts or component failure. Vacuum mixers ensure the materials’ integrity, supporting the production of reliable electronic devices.

In the pharmaceutical and medical sectors, they are critical for manufacturing oral drugs, injectables, and medical device components. For oral medications, uniform mixing of active pharmaceutical ingredients (APIs) with excipients is essential to ensure accurate dosage. In injectables, air bubbles are life-threatening, so vacuum mixers’ air-elimination capability is non-negotiable. They also aid in producing biocompatible materials for implants, where consistency and purity are mandatory.

The food and beverage industry uses vacuum mixers for high-end products like chocolate, sauces, and dairy-based desserts. For chocolate, removing air prevents a dull finish and ensures a smooth mouthfeel. In thick sauces or jams, uniform mixing avoids ingredient separation, while vacuum conditions preserve flavor by reducing oxidation. They also assist in producing low-oxygen products like modified-atmosphere packaged (MAP) foods, extending shelf life.

Lastly, the new materials sector—including composites, advanced ceramics, and renewable energy components—depends on vacuum mixers. For composite materials (e.g., carbon fiber-reinforced polymers), they ensure even resin-impregnation, boosting mechanical strength. In solar panel manufacturing, they mix electrode pastes without bubbles, enhancing energy conversion efficiency. This versatility across high-tech and consumer industries solidifies their role as a vital processing tool.

Gangben Mixer Manufacturer specializes in the research, development, production, and sales of mixing machines and filling machines. Its main products include vacuum emulsifying mixers, high-shear emulsifying mixers, vacuum homogenizing emulsifiers, filling and sealing machines, and liquid filling production lines. Equipped with modern production workshops and environments, we adopt advanced equipment manufacturing technologies and strict process quality management and control measures to ensure that all products are free from defects before leaving the factory.

Gangben Mixer Factory has obtained multiple patents for the research and development of emulsifying machines and planetary mixers, as well as ISO quality management system certification and international CE certification. Our products meet quality standards with a reliable quality guarantee. We are committed to manufacturing high-quality mixing machinery to enhance your production efficiency and reduce costs for your company.

-

PrevNone

-

Next50L Planetary Vacuum Mixer

English

English Russian

Russian French

French Spanish

Spanish Portuguese

Portuguese Korean

Korean Japanese

Japanese Thai

Thai