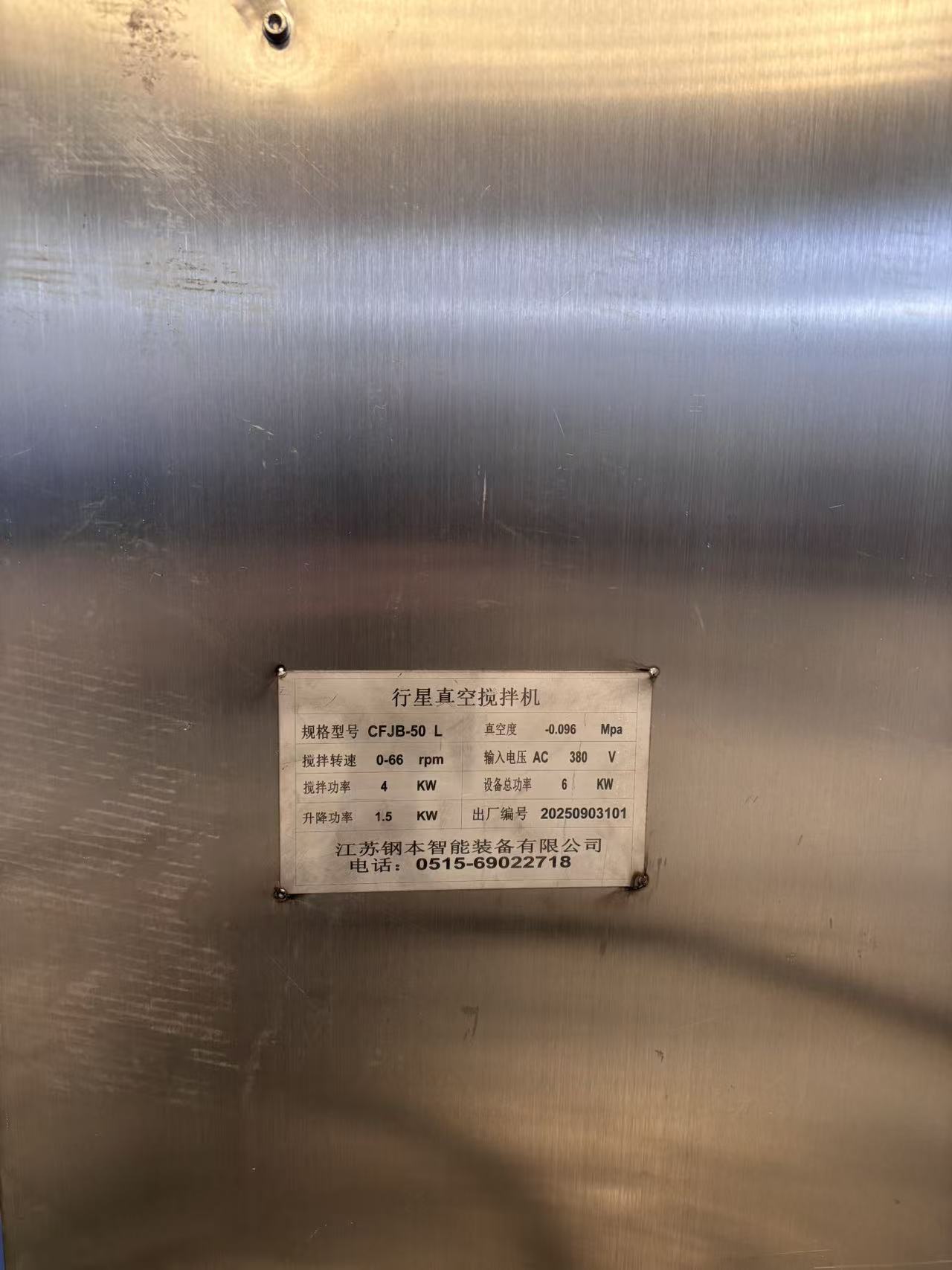

50L Planetary Vacuum Mixer

The 50L Planetary Vacuum Mixer integrates planetary mixing and vacuum technology, with a 50L capacity. It eliminates air bubbles, prevents oxidation, and ensures uniform stirring, ideal for high-demand industries like adhesives, pharmaceuticals, and food. Featuring stable operation, safety protection, and easy cleaning, it handles high-viscosity materials, meets purity requirements, and suits small-batch production and lab use.

Always on time

Always on time Acceptable price

Acceptable price Excellent quality

Excellent quality

Description

Feature&Application

Factory Strength

The 50L Planetary Vacuum Mixer is a high-performance equipment that combines two key technologies—planetary mixing and vacuum environment—making it a go-to choice for industries requiring high material purity and uniform mixing. With a 50-liter effective capacity, it balances small-batch production needs of factories and precision requirements of laboratories, widely applied in multiple fields.

In terms of core working principles, it adopts a dual-action planetary structure: the mixing paddle rotates around its own axis while revolving along the mixing bucket’s inner wall, ensuring no dead corners for thorough stirring. Meanwhile, the built-in vacuum system extracts air from the bucket during operation, effectively removing air bubbles in materials, avoiding oxidation and moisture absorption, and maintaining material stability and purity—critical for products like high-end coatings, pharmaceutical powders, and food fillings.

In performance, the equipment is equipped with a high-torque motor and a precision transmission system, enabling smooth operation even when handling high-viscosity materials such as resins and pastes, with low noise and long service life. It also has multiple safety designs, including overload protection, vacuum pressure monitoring, and emergency stop buttons, ensuring operator safety and stable production.

For applications, it shines in various industries: in the chemical sector, it mixes adhesives, pigments, and electronic potting compounds; in pharmaceuticals, it processes sterile powders and medicinal pastes; in food, it stirs low-oxygen requirement fillings and sauces. Additionally, it supports customization—options like heating/cooling jackets or explosion-proof components cater to specific industry needs.

Operation and maintenance are user-friendly. The intuitive control panel allows easy setting of vacuum degree, mixing speed, and time; the detachable mixing bucket and paddle simplify cleaning, complying with hygiene standards of food and pharmaceutical industries, and reducing enterprise operating costs.

Features

Dual-Technology Integration

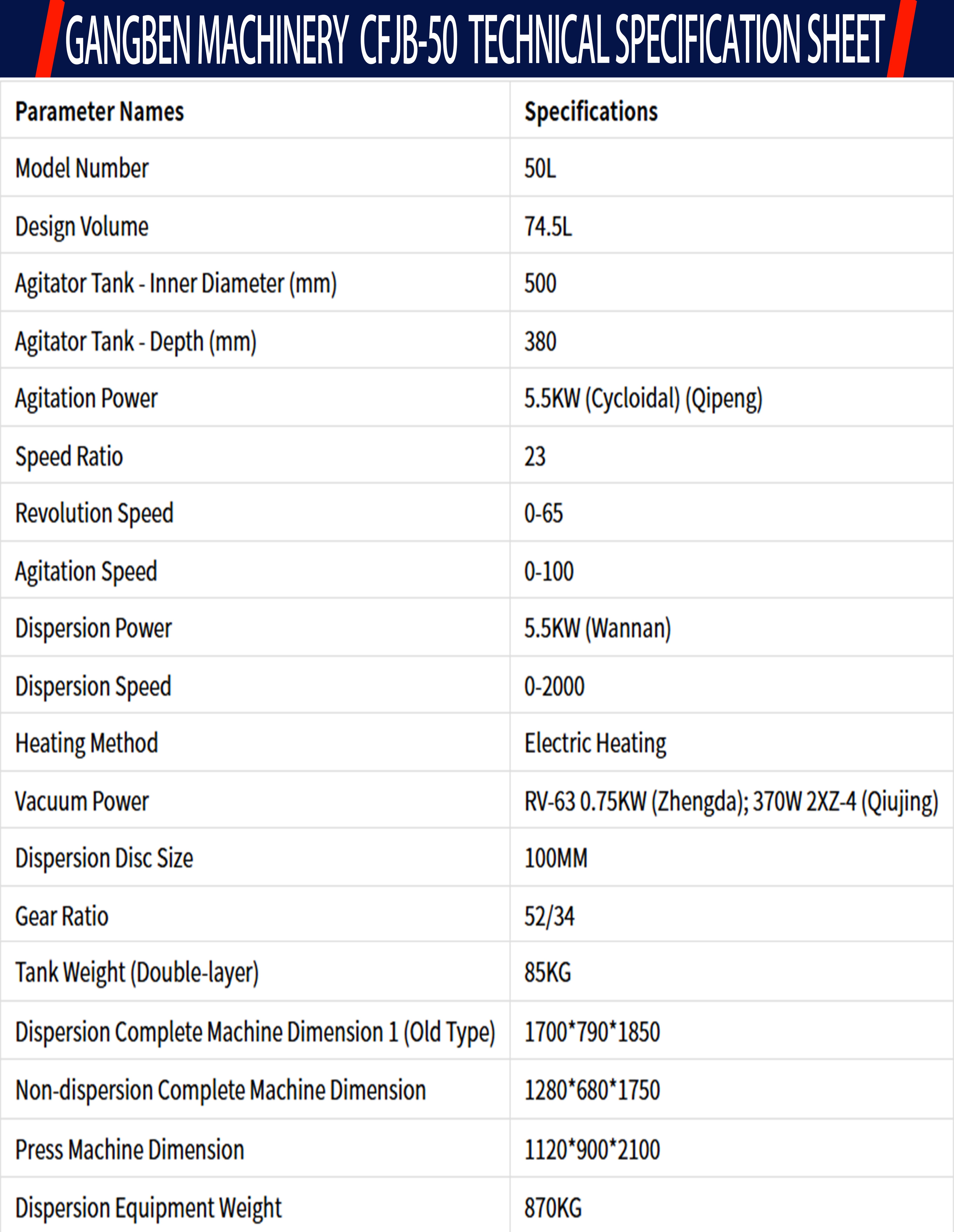

Combines planetary mixing and vacuum systems: The planetary trajectory (paddle rotation + revolution) ensures 360° dead-corner-free stirring for uniform mixing; the vacuum function (adjustable vacuum degree up to -0.098MPa) removes air bubbles, prevents material oxidation and moisture absorption, and maintains high product purity.

Strong Material Adaptability

With a 50L capacity and high-torque motor, it handles various materials—from low-viscosity liquids (e.g., coatings) to high-viscosity pastes (e.g., resins, adhesives) and even powder-granule mixtures (e.g., pharmaceutical powders), without compromising mixing efficiency.

Precise & Safe Operation

Equipped with an intuitive touch control panel, supporting adjustable mixing speed (0-60rpm), vacuum retention time, and automatic stop function for precise process control.

Built-in safety protections: Overload protection, vacuum pressure abnormal alarm, and emergency stop button to avoid equipment damage and ensure operator safety.

Easy Maintenance & Hygiene Compliance

Detachable mixing bucket and stainless steel (304/316L optional) mixing paddles for easy disassembly, cleaning, and sterilization.

Smooth inner wall of the bucket prevents material residue, meeting GMP standards for food, pharmaceutical, and cosmetic industries.

Customizable Configurations

Optional add-ons: Heating/cooling jackets (for temperature-sensitive materials), explosion-proof components (for flammable chemicals), and liquid feeding ports (for continuous mixing), adapting to diverse production needs.

Application Areas

Chemical & New Material Industry

Ideal for mixing adhesives, electronic potting compounds, UV resins, and high-performance coatings. The vacuum function eliminates bubbles to enhance product bonding strength and surface smoothness; high-viscosity adaptability suits rubber and plastic raw material mixing.

Pharmaceutical & Healthcare Industry

Applied in mixing pharmaceutical powders (e.g., antibiotic powders), herbal extracts, and medical ointments. Complies with GMP standards, ensures no cross-contamination, and the vacuum environment maintains the stability of active pharmaceutical ingredients (APIs) without oxidation.

Food & Cosmetic Industry

Food sector: Mixes low-oxygen-requirement products like chocolate fillings, fruit jams, and dairy creams—prevents bacterial growth and preserves flavor.

Cosmetic sector: Prepares emulsions, facial masks, and lipsticks, removing bubbles to ensure product texture is fine and smooth.

Laboratory & Small-Batch Production

Suitable for R&D labs in universities, research institutes, and enterprises. The 50L capacity meets small-batch trial production needs, supporting formula optimization for new materials (e.g., battery electrolytes, composite materials) with precise process control.

Aerospace & Electronic Industry

Used for mixing high-precision materials such as electronic adhesive films, satellite component potting compounds, and semiconductor packaging materials. The vacuum and uniform mixing ensure material performance stability, critical for high-tech product quality.

Gangben Mixer Manufacturer specializes in the research, development, production, and sales of mixing machines and filling machines. Its main products include vacuum emulsifying mixers, high-shear emulsifying mixers, vacuum homogenizing emulsifiers, filling and sealing machines, and liquid filling production lines. Equipped with modern production workshops and environments, we adopt advanced equipment manufacturing technologies and strict process quality management and control measures to ensure that all products are free from defects before leaving the factory.

Gangben Mixer Factory has obtained multiple patents for the research and development of emulsifying machines and planetary mixers, as well as ISO quality management system certification and international CE certification. Our products meet quality standards with a reliable quality guarantee. We are committed to manufacturing high-quality mixing machinery to enhance your production efficiency and reduce costs for your company.

English

English Russian

Russian French

French Spanish

Spanish Portuguese

Portuguese Korean

Korean Japanese

Japanese Thai

Thai