Automatic/Semi-automatic Metal Tube Filling And Sealing Machine

The Semi-automatic Metal Tube Filling and Sealing Machine is a flexible packaging solution for metal tubes, suitable for small-to-medium batches in pharmaceuticals, cosmetics, and adhesives. It features manual tube loading with precise piston filling (±1.5% accuracy) and reliable crimp sealing. Constructed with 304 stainless steel, it complies with GMP standards. Compact, easy to operate and maintain, it adapts to tube diameters 8-50mm and tube heights 50-180mm, ideal for businesses needing versatile, cost-effective packaging.

Always on time

Always on time Acceptable price

Acceptable price Excellent quality

Excellent quality

Description

Feature&Application

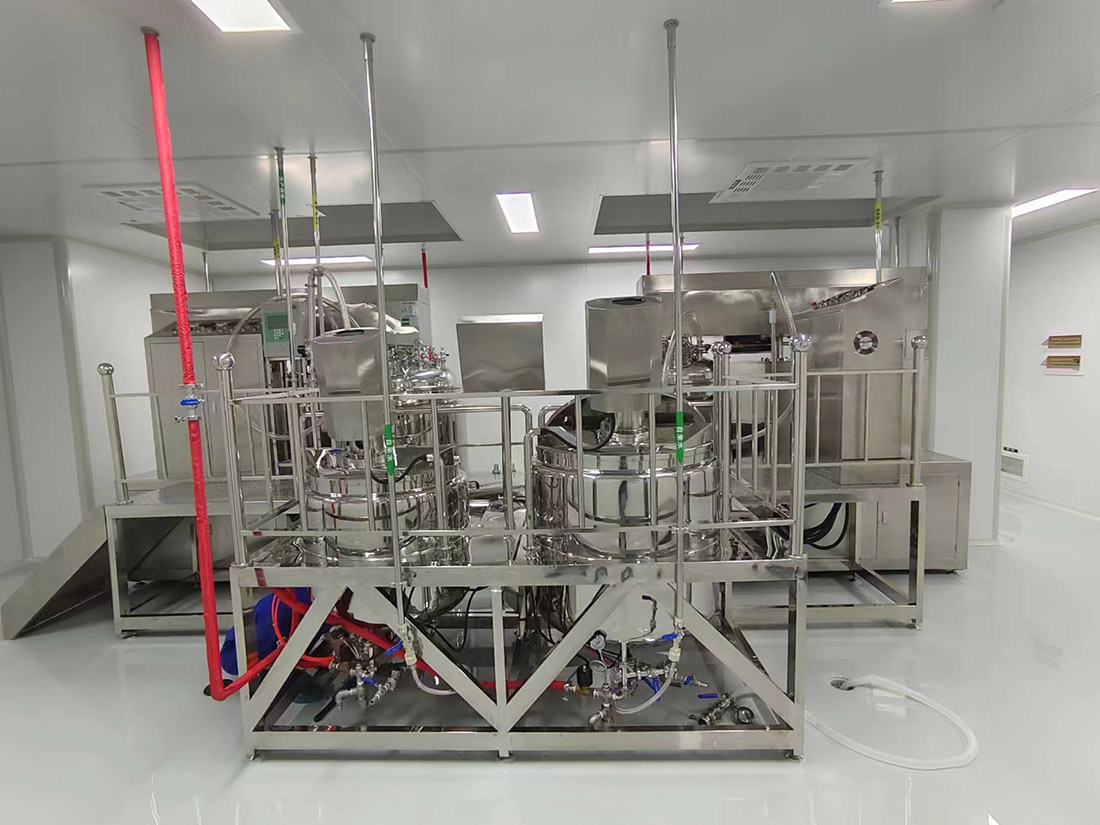

Factory Strength

Filling and sealing machine adopts closed and semi-closed filling paste, liquid,sealing with no leakage, filling weight, capacity, good consistency, a complete filling, sealing, printing, applicable to the pharmaceutical, cosmetic, food, chem-ical industry in areas such as product packaging. Such as: dermatitis, ointment,hair dye, toothpaste, shoe polish, adhesives,AB glue, epoxy glue, chloroprene and other materials filling and sealing. It is the ideal practical and economical filling equipment of medicine, daily chemical and fine chemical industry.

Performance characteristics:

1. The transmission part is closed under the platform, safe and reliable, without pollution;

2. The filling and sealing part shall be installed in the semi-enclosed non-static outer frame of the platform, easy to observe, easy to operate and easy to maintain;(optional)

3. PLC control, human-computer dialogue interface;

4. The rotary disc is driven by the CAM, with high speed and high precision;

5. Photoelectric to standard workstation, with high precision probe, stepper motor and other control hose design in the correct position;

6. The nozzle is equipped with a cutting mechanism to ensure the filling quality;

7. No pipe and no filling;

8. The type-code workstation automatically prints the characters in the position of process requirements;

9. Fault protection alarm, no pipe alarm, door open and stop, overload stop;

10. Counting and quantitative stop.

-

PrevNone

-

NextAutomatic plastic Tube Filling And Sealing Machine

Recommend Products

Recommend Faq

-

Sep 04,2025

Sep 04,2025Lab Emulsifier Mixer Buying Guide: 5 Key Parameters for Optimal Homogenization Performance

-

Sep 04,2025

Sep 04,2025Vacuum Emulsifying Homogenizer: How to Achieve Nano-Scale Dispersion for High-Viscosity Materials?

-

Aug 27,2025

Aug 27,20252025 Emulsifying Homogenizer Market Report: Trends, Growth Drivers & Competitive Landscape

English

English Russian

Russian French

French Spanish

Spanish Portuguese

Portuguese Korean

Korean Japanese

Japanese Thai

Thai