From Lab to Pilot Scale: Modular Homogenizer Mixers Cut R&D Costs by 60% for CBD and Hemp Oil Emulsions

In the development of CBD (cannabidiol) and hemp oil emulsions, the transition from laboratory to pilot scale has long been a critical bottleneck, constraining both cost efficiency and production effectiveness. Traditional equipment often faces challenges such as high energy consumption, uneven mixing, and difficulties in linearly scaling up process parameters during production expansion, resulting in soaring research and development (R&D) costs. Jiangsu GangBen Mixer Manufacturer has achieved a breakthrough by innovating modular homogenization and mixing technology, successfully reducing R&D costs for CBD and hemp oil emulsions by 60% and providing a replicable solution for large-scale production in the industry.

I. The Pain Points of Traditional Processes: The "Discontinuity" from Lab to Pilot Scale

At the laboratory stage, researchers typically use small-scale homogenizers or ultrasonic disruptors to prepare CBD emulsions. While these devices can achieve nanoscale particle size control, when production volume increases from 500 mL to 50 L, the energy consumption of traditional high-pressure homogenizers grows exponentially. For instance, when a company produced 1,000 L of CBD emulsion using traditional equipment, the energy consumption of the homogenization process alone accounted for 35% of the total production cost, and the stability difference between batches exceeded 15%.

An even more severe challenge lies in the non-linear scaling of process parameters. The 20 MPa homogenization pressure used in the laboratory may result in insufficient shear force during large-scale production due to changes in fluid dynamics. Conversely, blindly increasing the pressure can lead to the following issues:

Degradation of active ingredients: CBD is prone to isomerization under high temperature and pressure, resulting in a loss of over 20% of effective components.

Increased equipment wear: The wear rate of titanium alloy components in traditional homogenization valves triples under high pressure, leading to a surge in maintenance costs.

Reduced emulsion stability: The standard deviation of particle size distribution expands from 0.2 μm in the laboratory to 0.8 μm during pilot-scale production, causing phase separation.

II. GangBen's Modular Breakthrough: Three Innovations Redefining Production Logic

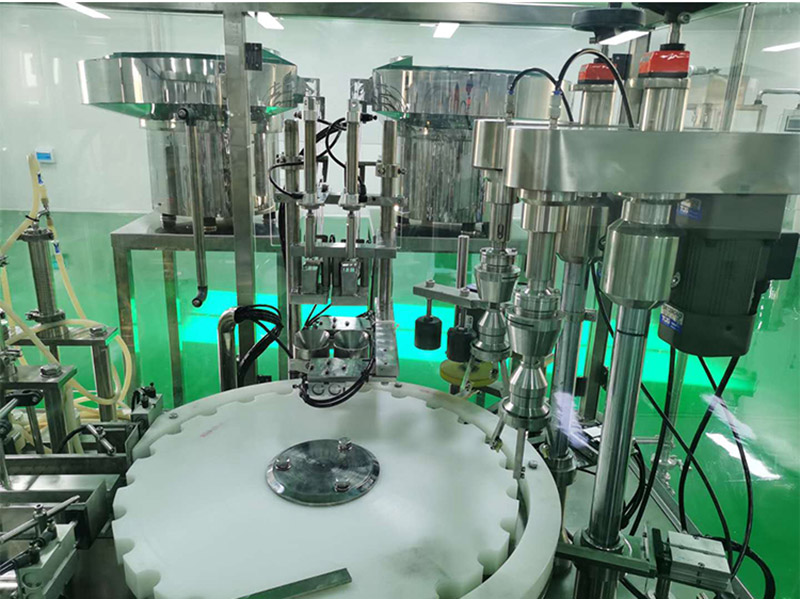

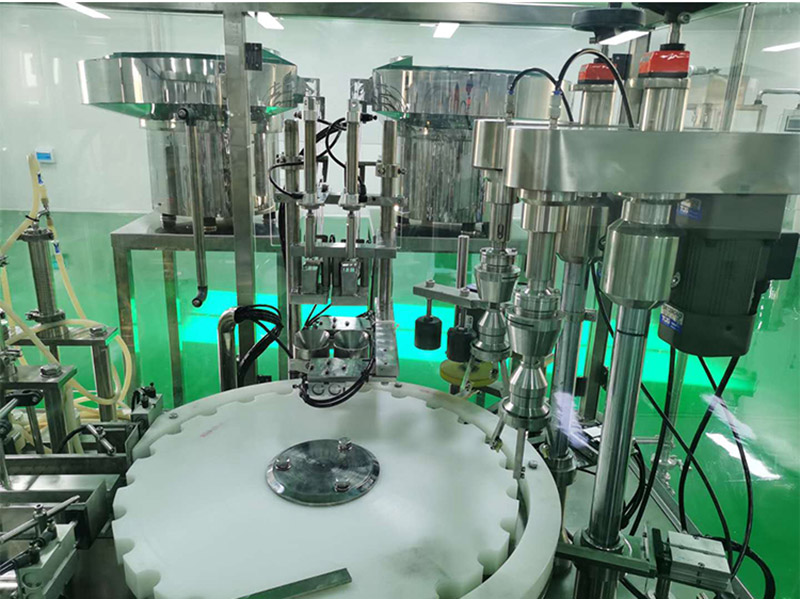

By integrating computational fluid dynamics (CFD) simulations and materials science, Jiangsu GangBen Mixer Manufacturer has developed the world's first Modular Homogenizer Mixer (MHM) system, featuring three core innovations:

1. Dynamic Pressure Compensation Module

Traditional homogenizers use fixed homogenization valves, while the MHM system incorporates pressure sensors and intelligent regulating valves that continuously monitor fluid resistance and automatically adjust the valve clearance. In a pilot production project with a client, this technology reduced the pressure fluctuation range from ±5 MPa to ±0.8 MPa, ensuring that the D90 particle size of CBD emulsion remained stable below 180 nm, improving stability by 40% compared to traditional equipment.

2. Multi-Stage Shear Synergy Module

Drawing inspiration from the design of double-planetary mixers in the food industry, the MHM system combines high-pressure homogenization with high-shear emulsification in a modular configuration. When processing high-viscosity hemp oil matrices, the system first achieves pre-dispersion through double-layer scraper-wall stirring, followed by nanoscale crushing via high-pressure homogenization. This staged approach reduces energy consumption by 55% while maintaining viscosity control precision at ±2 cP (laboratory-grade standards).

3. Rapid Tooling Change Module

To address the diverse needs of CBD products, GangBen developed a quick-release homogenization head design. By replacing diamond-coated homogenization valves with different pore sizes, a single machine can accommodate both oil-in-water (O/W) and water-in-oil (W/O) emulsion systems. Client testing shows that product type switching time has been reduced from 8 hours with traditional equipment to just 45 minutes, increasing overall equipment utilization by 300%.

III. Pilot-Scale Data Validation: Dual Improvements in Cost and Efficiency

In a 2024 collaboration project with a listed company, the MHM system demonstrated significant advantages:

Cost Comparison: Traditional processes incurred a total cost of RMB 128,000 to produce 1,000 L of CBD emulsion, with the homogenization step accounting for RMB 45,000. Using the MHM system, the total cost dropped to RMB 51,000, a 60% reduction, with RMB 32,000 saved in the homogenization process alone.

Efficiency Gains: The pilot batch cycle was shortened from 72 hours to 18 hours, with equipment footprint reduced by 65% and personnel requirements cut from 5 to 2.

Quality Metrics: Stability tests showed that the phase separation time aft

Related product links

News

- Latest News

- Solutions

- FAQ

Recommend Products

-

10L Vacuum Emulsifying Mixer

10L Vacuum Emulsifying Mixer10L Vacuum Emulsifying Mixer is a device used for emulsifying and mixing various substances in a vacuum environment. It is commonly used in industries such as food, cosmetics, and pharmaceuticals.

-

20L Vacuum Emulsifying Mixer

20L Vacuum Emulsifying Mixer20L vacuum emulsifying mixer is a device used for emulsifying and mixing various substances in a vacuum environment. It has a larger capacity and is suitable for handling larger batches of materials.

-

30L Emulsifying Homogenizer Mixer

30L Emulsifying Homogenizer Mixer30L Emulsifying Homogenizer Mixer is a high-speed emulsifying homogenizer mixer that is suitable for various emulsification and homogenization applications. It can be used to mix and emulsify various liquids, such as water, oil, and other liquids, to achieve a stable emulsion.

Recommend Faq

-

Jul 10,2025

Jul 10,2025How to Choose a Vacuum Emulsifying Mixer: Key Factors for Food & Chemical Processing

-

Jul 10,2025

Jul 10,2025From Lab to Pilot Scale: Modular Homogenizer Mixers Cut R&D Costs by 60% for CBD and Hemp Oil Emulsions

-

Jul 02,2025

Jul 02,2025Precision Emulsification Redefined: How Jiangsu GangBen Mixer Manufacturer’s Advanced Emulsifying Machines Set Global Industry Benchmarks

English

English Russian

Russian French

French Spanish

Spanish Portuguese

Portuguese Korean

Korean Japanese

Japanese Thai

Thai