How to Choose a Vacuum Emulsifying Mixer: Key Factors for Food & Chemical Processing

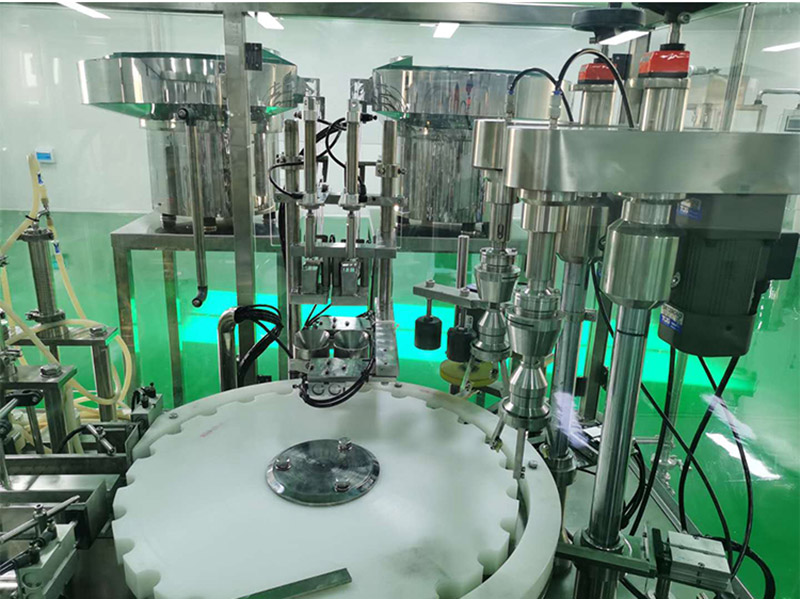

In the food and chemical processing industries, vacuum emulsifying mixers are critical equipment for producing stable emulsions, creams, and suspensions. Their performance directly impacts product quality, production efficiency, and regulatory compliance. This article analyzes key selection criteria from three dimensions—core technical parameters, industry-specific adaptability, and supplier capabilities—using Jiangsu GangBen Mixer Manufacturer as a case study to illustrate the defining features of high-quality equipment.

1. Core Performance Parameters: Determining Emulsification Quality and Efficiency

1.1 Vacuum Level and Sealing Integrity

A vacuum environment eliminates air bubbles during emulsification, enhancing product stability. Premium equipment requires a high-precision vacuum system (e.g., pumps achieving ≥-0.095 MPa) paired with mechanical or magnetic seals for long-term leak-free operation. For instance, GangBen’s vacuum emulsifiers utilize dual mechanical seals with 316L stainless steel construction, maintaining stable vacuum levels after 2,000+ continuous operating hours and minimizing oxidation risks.

1.2 Homogenization and Mixing Systems

Homogenizer Design: High-shear homogenizing heads (e.g., GangBen’s modular diamond-coated valves) enable particle size control between 180–500 nm, suitable for high-viscosity materials like peanut butter or cosmetic creams.

Mixing Speed and Torque: Motors must support stepless speed adjustment (0–85 RPM) to handle diverse formulations. GangBen’s 50L model, equipped with a 7.5 kW motor, processes materials up to 50,000 cP viscosity, meeting demands from food (e.g., chocolate spread) and chemical (e.g., resin) sectors.

1.3 Heating and Cooling Capabilities

Food processing often requires precise temperature control (e.g., 85°C ±2°C for dairy pasteurization), while chemical synthesis may involve low-temperature reactions (e.g., polymer production). GangBen offers triple heating/cooling options: electric, steam, and jacketed circulation cooling. Its 200L unit achieves a 3°C/min heating rate with ±1°C temperature stability, complying with FDA and GMP standards.

2. Industry-Specific Adaptability: Customized Solutions from Food to Chemicals

2.1 Food Industry Requirements

Hygiene Standards: Equipment must feature mirror-polished surfaces (Ra ≤0.4 μm) and full 316L stainless steel construction to prevent metal contamination. GangBen’s mixers are CE-certified, with CIP-compatible piping systems that reduce manual cleaning and microbial risks.

Versatility: Food formulations often contain particulates (e.g., nuts, fruit pieces), necessitating scraper agitators. GangBen’s FMB-200 model uses a helical scraper design to eliminate wall residue, ensuring uniform homogenization.

2.2 Chemical Industry Demands

Corrosion Resistance: Chemical feedstocks (e.g., acids, solvents) demand advanced materials. GangBen provides Hastelloy and titanium alloy options, with its 500L unit showing ≤0.02 mm/year corrosion rates when processing 30% sulfuric acid—triple the lifespan of standard equipment.

Explosion Protection: For flammable materials (e.g., organic solvents), ATEX-certified designs with explosion-proof motors and electrostatic grounding are essential. GangBen’s equipment incorporates flameproof control cabinets for safe handling of liquids with flash points below 60°C.

3. Supplier Capabilities: Technical Expertise and After-Sales Support

3.1 R&D and Manufacturing Strength

Select suppliers with in-house design capabilities to ensure equipment adaptability. GangBen’s 20-year R&D experience enables rapid customization from 10L lab units to 5,000L production-scale mixers. For example, its dynamic pressure compensation homogenization system, developed for a CBD client, improved emulsion stability by 40% while cutting R&D costs by 60%.

3.2 Quality Control Systems

Leading suppliers adhere to ISO 9001/14001 certifications and implement full traceability. GangBen assigns unique IDs to each unit, subjecting them to 12 inspection stages, including vacuum leakage tests, load operation trials, and particle size distribution verification.

3.3 Global Service Network

Equipment failures can halt production lines, necessitating rapid response services. GangBen operates 12 regional service centers in China, guaranteeing on-site repairs within 48 hours. Its remote diagnostics system monitors real-time parameters to preempt failures, reducing unplanned downtime.

Choosing a vacuum emulsifying mixer requires evaluating technical performance, industry fit, and supplier reliability. Jiangsu GangBen Mixer Manufacturer stands out with its modular design, end-to-end quality control, and responsive service, making it a preferred partner for food and chemical processors. As industries embrace smart manufacturing and sustainability, innovative suppliers like GangBen will continue driving techno

News

- Latest News

- Solutions

- FAQ

Recommend Products

-

10L Vacuum Emulsifying Mixer

10L Vacuum Emulsifying Mixer10L Vacuum Emulsifying Mixer is a device used for emulsifying and mixing various substances in a vacuum environment. It is commonly used in industries such as food, cosmetics, and pharmaceuticals.

-

20L Vacuum Emulsifying Mixer

20L Vacuum Emulsifying Mixer20L vacuum emulsifying mixer is a device used for emulsifying and mixing various substances in a vacuum environment. It has a larger capacity and is suitable for handling larger batches of materials.

-

30L Emulsifying Homogenizer Mixer

30L Emulsifying Homogenizer Mixer30L Emulsifying Homogenizer Mixer is a high-speed emulsifying homogenizer mixer that is suitable for various emulsification and homogenization applications. It can be used to mix and emulsify various liquids, such as water, oil, and other liquids, to achieve a stable emulsion.

Recommend Faq

-

Jul 10,2025

Jul 10,2025How to Choose a Vacuum Emulsifying Mixer: Key Factors for Food & Chemical Processing

-

Jul 10,2025

Jul 10,2025From Lab to Pilot Scale: Modular Homogenizer Mixers Cut R&D Costs by 60% for CBD and Hemp Oil Emulsions

-

Jul 02,2025

Jul 02,2025Precision Emulsification Redefined: How Jiangsu GangBen Mixer Manufacturer’s Advanced Emulsifying Machines Set Global Industry Benchmarks

English

English Russian

Russian French

French Spanish

Spanish Portuguese

Portuguese Korean

Korean Japanese

Japanese Thai

Thai