The 200L disperser

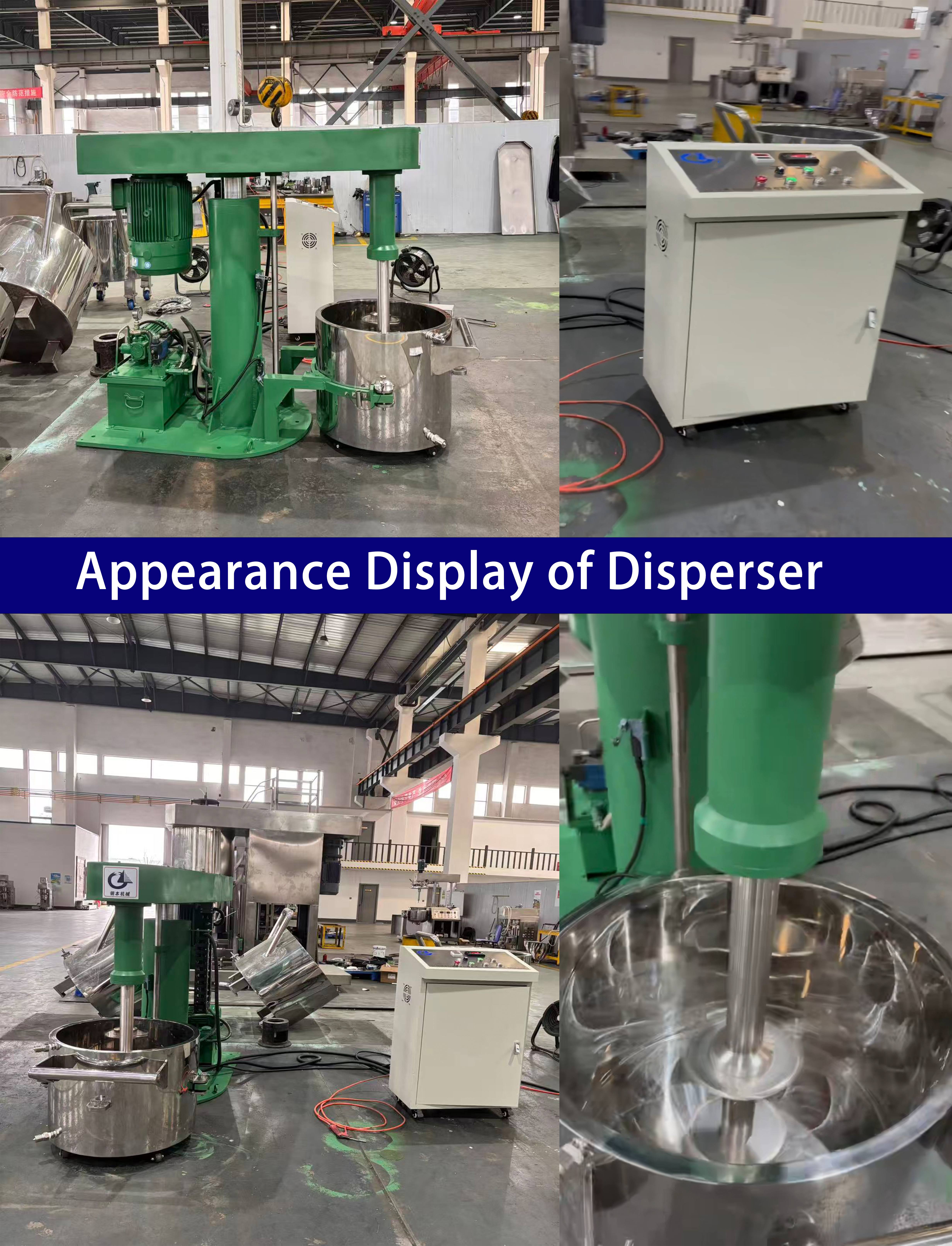

The 200L disperser is a high-performance industrial equipment designed for efficient mixing and dispersion of various materials, with a maximum processing capacity of 200 liters. It features a powerful motor (typically 15 - 22kW) and an adjustable speed range (0 - 1500rpm), enabling it to handle different viscosities of materials like coatings, inks, adhesives, and pigments. Equipped with a robust mixing shaft and dispersing disc, it ensures uniform particle size reduction and thorough material integration. The machine adopts a user-friendly control panel for easy operation and monitoring, while its sturdy frame and safety guards guarantee stable operation and operator protection. Widely used in chemical, paint, and pharmaceutical industries, it significantly improves production efficiency and product quality.

Always on time

Always on time Acceptable price

Acceptable price Excellent quality

Excellent quality

Description

Feature&Application

Factory Strength

The 200L disperser is a key piece of equipment in modern industrial production, specifically engineered to address the challenges of mixing and dispersing large-volume materials. With a nominal capacity of 200 liters, it is tailored for medium to large-scale production lines, bridging the gap between small laboratory dispersers and oversized industrial mixers. Its primary function is to break down agglomerated particles, blend multiple components evenly, and create homogeneous mixtures, which is crucial for ensuring the performance and consistency of end products in various industries.

Motor and Power System: At the heart of the 200L disperser is a high-torque, three-phase asynchronous motor with a power rating ranging from 15kW to 22kW. This motor provides sufficient power to drive the dispersing mechanism, even when dealing with high-viscosity materials (up to 10,000 cP). The motor is equipped with a heat dissipation system to prevent overheating during long-term operation, extending its service life.

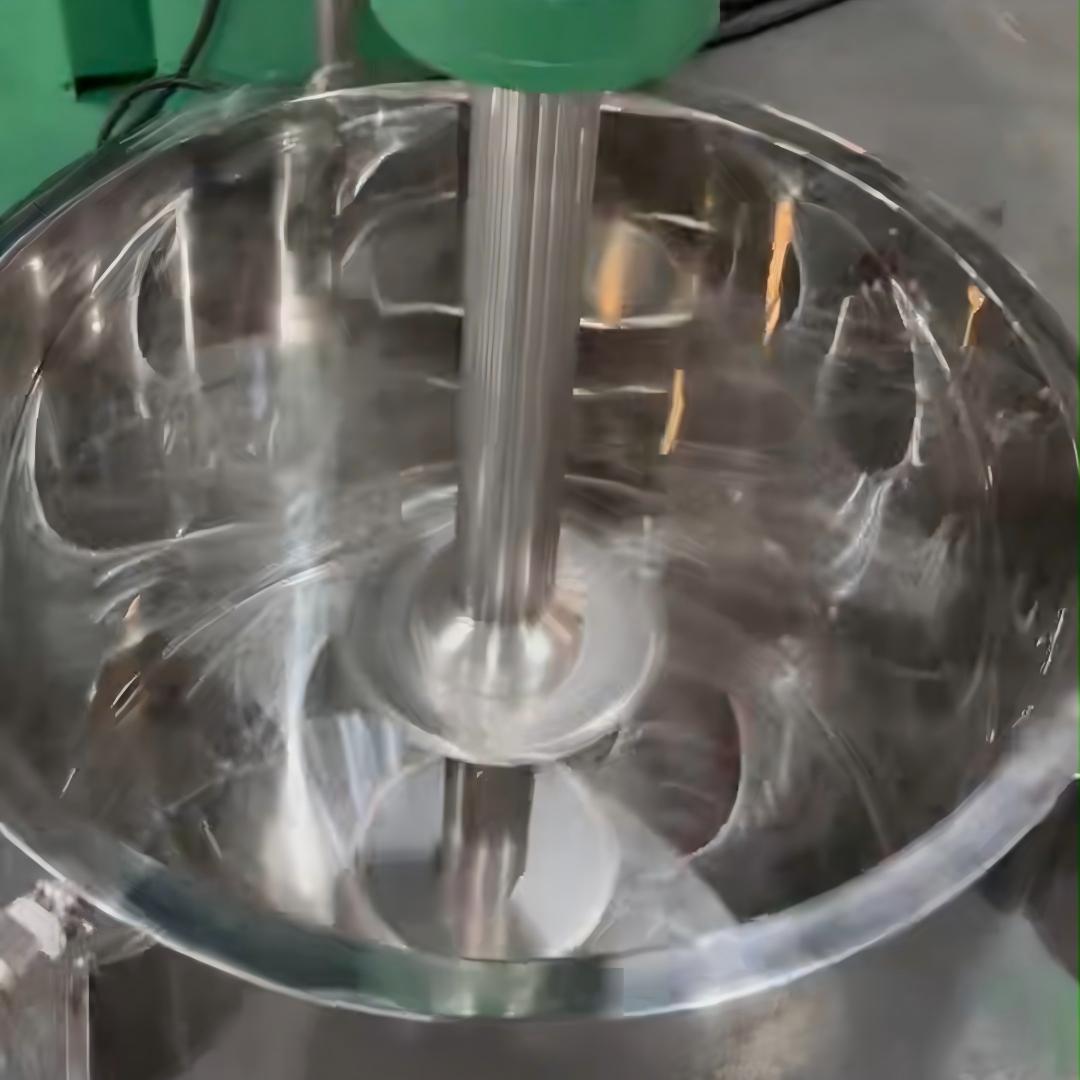

Dispersing Mechanism: The dispersing component consists of a high-strength stainless steel mixing shaft and a dispersing disc. The shaft is precision-machined to ensure smooth rotation and minimal vibration, while the disc features a special tooth structure that generates strong shearing and centrifugal forces. When rotating, the disc pulls materials from the bottom of the tank to the top, creating a turbulent flow that effectively breaks down particle agglomerates and mixes materials thoroughly. The diameter of the dispersing disc is typically 300 - 400mm, optimized to match the 200L tank volume for maximum dispersion efficiency.

Tank and Frame: The machine is paired with a 200L stainless steel tank (304 or 316L material) that is corrosion-resistant and easy to clean, making it suitable for food-grade and pharmaceutical applications. The tank is mounted on a movable trolley, allowing for easy transportation and positioning. The frame of the disperser is constructed from thickened steel plates, providing excellent stability and supporting the weight of the motor, shaft, and tank (total weight up to 800 - 1000kg). Safety guards are installed around the rotating parts to prevent accidents, and an emergency stop button is readily accessible on the control panel.

To ensure the long-term and stable operation of the 200L disperser, regular maintenance is necessary. This includes checking the motor oil level, tightening loose bolts, cleaning the dispersing disc and tank after use, and replacing worn parts (such as seals and bearings) periodically. Most manufacturers provide a one-year warranty and professional after-sales service, including on-site installation, training, and repair support. By following the maintenance guidelines and seeking timely service when needed, users can maximize the lifespan of the machine and minimize production downtime.

Performance Features

Adjustable Speed: The 200L disperser offers a wide speed range of 0 - 1500rpm, which can be adjusted steplessly via a frequency converter. This flexibility allows operators to select the optimal speed based on the material properties. For example, low speeds (300 - 600rpm) are used for initial mixing of low-viscosity materials, while high speeds (1000 - 1500rpm) are ideal for dispersing high-viscosity or agglomerated materials.

High Dispersion Efficiency: Thanks to the advanced dispersing disc design and powerful motor, the machine can achieve a particle size reduction of up to 1 - 5 microns for most materials. It ensures that the mixture is homogeneous with a uniform particle size distribution, reducing product defects and improving product quality. In a typical production process, the 200L disperser can complete the dispersion of a 200L batch of coating materials in 30 - 60 minutes, significantly faster than traditional mixing methods.

User-Friendly Operation: The control panel is designed with simplicity and functionality in mind, featuring clear indicators for speed, motor temperature, and operating status. Operators can easily set the desired speed, start/stop the machine, and monitor the operation parameters. Some advanced models also come with a touchscreen interface and a memory function, allowing operators to save and recall frequently used speed settings.

Application FieldsThe 200L disperser finds extensive applications in various industries due to its versatility and high performance:

Chemical Industry: It is used for mixing and dispersing resins, emulsions, and chemical additives, ensuring the stability and reactivity of chemical products.

Paint and Coating Industry: In paint production, the disperser is essential for dispersing pigments into the base paint, eliminating color spots and ensuring uniform color coverage. It is suitable for producing water-based paints, oil-based paints, and industrial coatings.

Adhesive and Sealant Industry: It helps blend polymers, fillers, and solvents to create high-quality adhesives and sealants with consistent viscosity and bonding strength.

Pharmaceutical and Food Industry: With food-grade stainless steel construction, the 200L disperser is used for mixing pharmaceutical ingredients, food additives, and liquid food products (such as sauces and syrups), complying with strict hygiene standards.

Gangben Mixer Manufacturer specializes in the research, development, production, and sales of mixing machines and filling machines. Its main products include vacuum emulsifying mixers, high-shear emulsifying mixers, vacuum homogenizing emulsifiers, filling and sealing machines, and liquid filling production lines. Equipped with modern production workshops and environments, we adopt advanced equipment manufacturing technologies and strict process quality management and control measures to ensure that all products are free from defects before leaving the factory.

Gangben Mixer Factory has obtained multiple patents for the research and development of emulsifying machines and planetary mixers, as well as ISO quality management system certification and international CE certification. Our products meet quality standards with a reliable quality guarantee. We are committed to manufacturing high-quality mixing machinery to enhance your production efficiency and reduce costs for your company.

English

English Russian

Russian French

French Spanish

Spanish Portuguese

Portuguese Korean

Korean Japanese

Japanese Thai

Thai