500L Vacuum Homogenizing Emulsifier Unit

The 500L Vacuum Emulsifying Unit is a high-capacity industrial equipment designed for large-batch, high-quality emulsification. Integrating a powerful rotor-stator system and vacuum technology, it eliminates air bubbles for smooth, stable products. Constructed with 316L stainless steel, it meets FDA, GMP, and CE standards. Equipped with digital control and safety features, it’s ideal for cosmetics, pharmaceuticals, and food industries requiring scalable, premium emulsification.

Always on time

Always on time Acceptable price

Acceptable price Excellent quality

Excellent quality

Description

Feature&Application

Factory Strength

The 500L Vacuum Emulsifying Unit is a heavy-duty, advanced solution engineered to meet the rigorous demands of medium-to-large-scale industrial production, specializing in creating premium, air-free emulsions critical for high-end products. It bridges efficiency and quality, making it indispensable for manufacturers prioritizing both scalability and product excellence.

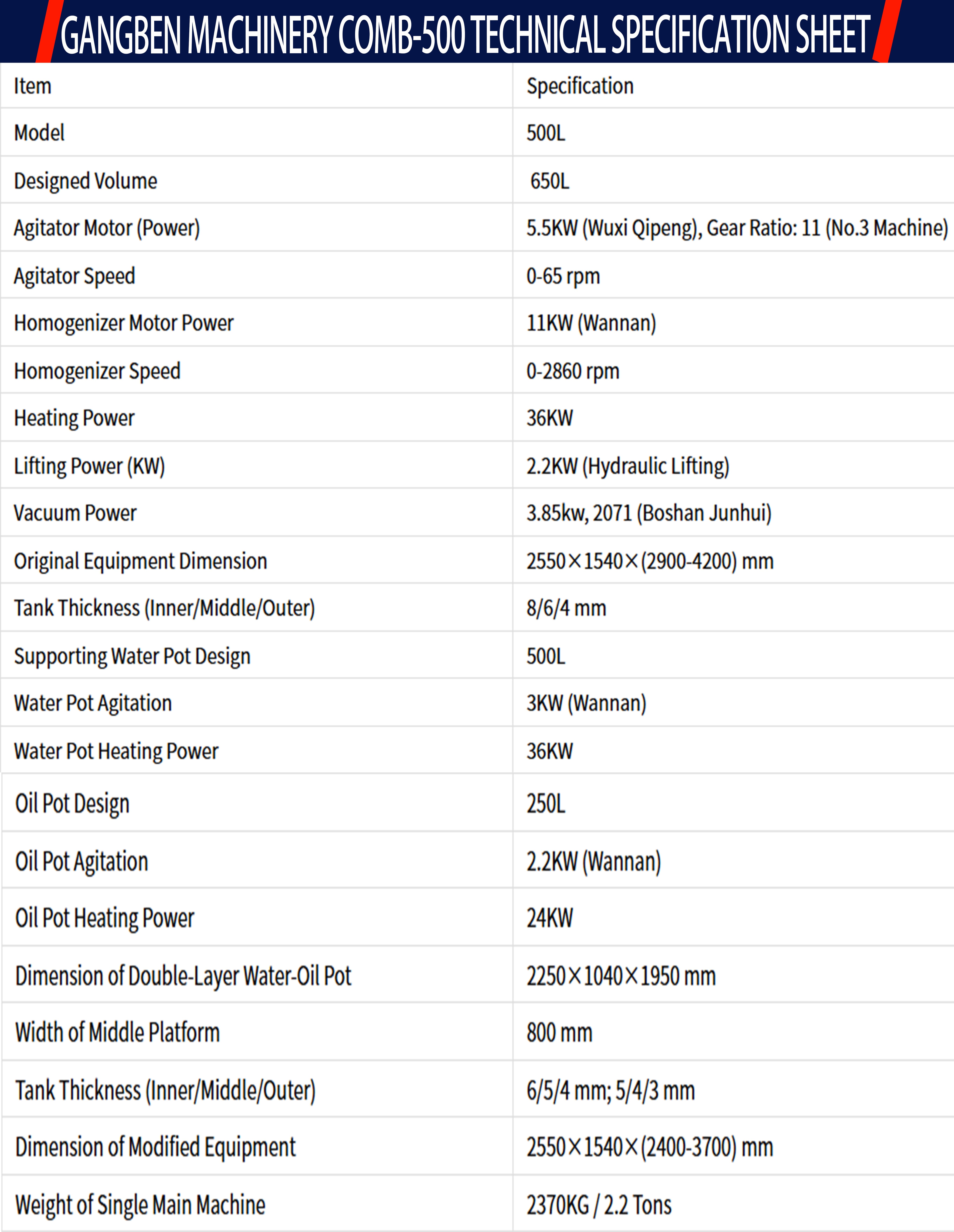

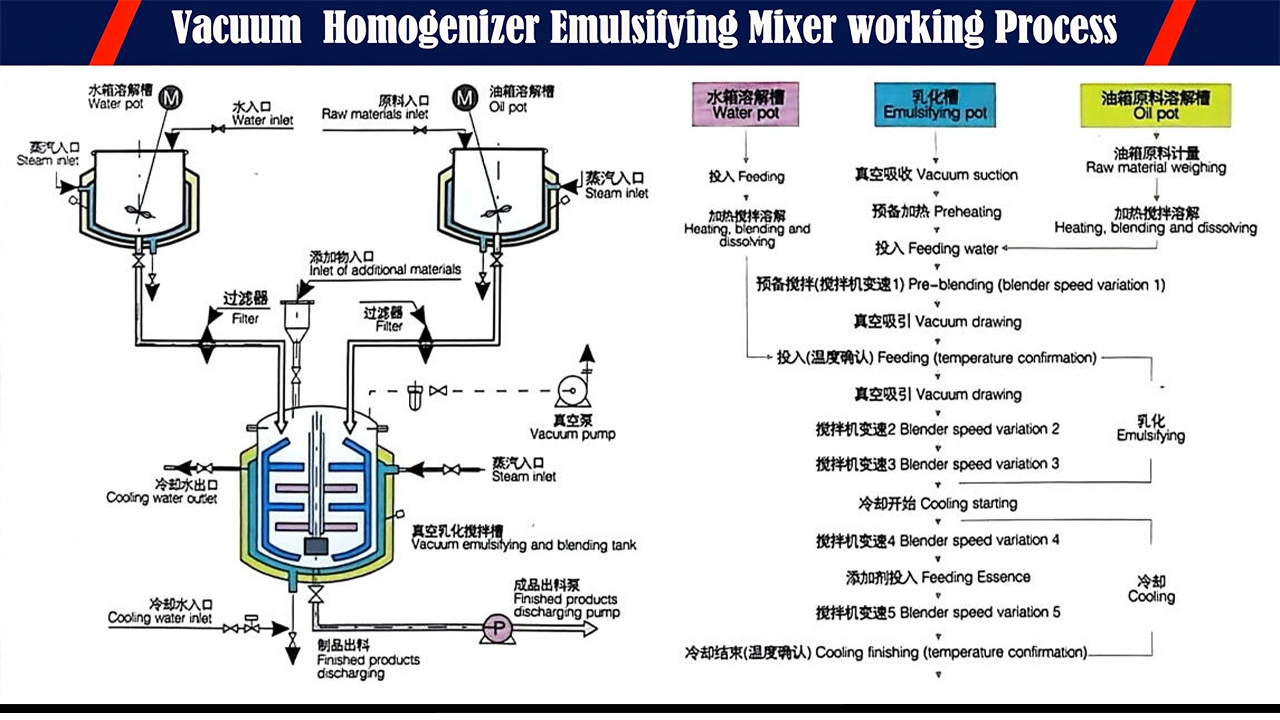

At its core, the unit combines a high-torque rotor-stator emulsifying head (0-2860 RPM adjustable) with a reliable vacuum system (up to -0.096MPa). The emulsifying head generates intense shear force to break down particles and mix phases uniformly, while the vacuum function removes air bubbles during processing—eliminating oxidation, ensuring a smooth texture, and extending product shelf life. This dual-system design is ideal for products like luxury creams, medical ointments, and high-grade food emulsions.Crafted from food-grade 316L stainless steel, all product-contact components (500L tank, emulsifying head, pipelines) feature mirror polishing to minimize residue and enable easy CIP (Clean-in-Place) cleaning. This construction complies with global regulatory standards (FDA, GMP, CE), meeting strict hygiene requirements for sensitive industries.

The intuitive PLC digital control panel allows precise programming of speed, vacuum level, temperature, and processing time, ensuring repeatable batch consistency. Safety is enhanced with emergency stop buttons, tank cover interlocks, and pressure/vacuum overload protection. Its rugged frame supports stable operation, while optional configurations (heating/cooling jackets, homogenizers) add versatility.

Widely adopted in cosmetics for bulk luxury skincare, pharmaceuticals for medical emulsions, and food processing for premium sauces, the 500L Vacuum Emulsifying Unit delivers efficient, compliant, and high-quality production, making it a valuable asset for scalable industrial operations.

Gangben Mixer Factory produces a variety of vacuum homogenizing emulsifiers. Its homogenizing system is divided into upper homogenization, lower homogenization, and internal-external circulation homogenization; the mixing system adopts positive and negative bidirectional wall-mounted mixing paddles; the lifting system is divided into electric lifting and hydraulic lifting. The factory can customize high-quality emulsifying machine products of various specifications according to customer requirements. The triple mixing adopts imported inverter for speed regulation, which can meet the production needs of different processes.

It adopts imported mechanical seals with excellent performance and German homogenizing structure technology, with the maximum emulsification speed reaching 3400 RPM and the minimum shear fineness reaching 0.2~5μm.

Vacuum defoaming enables materials to meet aseptic requirements, and vacuum suction is adopted—especially for powder materials, as vacuum inhalation can avoid dust flying.

The main pot cover can be equipped with an optional lifting device, which enhances the cleaning effect, and the pot body can be tilted for discharging.

The pot body is welded with three layers of imported stainless steel plates, and the tank body and pipelines are polished or matte-finished, fully complying with GMP requirements.

The tank can heat and cool materials, with the main heating methods being steam heating and electric heating.

To ensure more stable control of the entire machine, the electrical components are imported and fully meet international technical standards.

Application Area

Vacuum emulsifying mixers are used in many application areas, as follows:

Daily chemical products: Used in the production of emulsions, creams, shampoos, shower gels, etc.

Biomedicine: Used in the production of medical emulsions, ointments, oral liquids, etc.

Food industry: Used in the production of emulsified foods, such as yogurt, ice cream, cheese, etc.

Paint and ink: Used in the production of emulsified paints and inks.

Nanomaterials: Used in the preparation of nanomaterials.

Petrochemical industry: Used in the production of emulsified petroleum products.

Printing and dyeing auxiliaries: Used in the production of emulsified paper treatment agents.

Pesticides and fertilizers: Used in the production of emulsified pesticides and fertilizers.

Plastic and rubber: Used in the production of emulsified plastic and rubber materials.

Electric power and electronics industry: Used in the production of emulsified insulation materials and electronic components.

Other fine chemical engineering fields: Such as ceramics, glass, metal processing, etc.

In short, vacuum emulsifying machines have a wide range of applications and are mainly used to produce emulsified products, helping to improve product stability and performance in various industries.Gangben Mixer Manufacturer specializes in the research, development, production, and sales of mixing machines and filling machines. Its main products include vacuum emulsifying mixers, high-shear emulsifying mixers, vacuum homogenizing emulsifiers, filling and sealing machines, and liquid filling production lines. Equipped with modern production workshops and environments, we adopt advanced equipment manufacturing technologies and strict process quality management and control measures to ensure that all products are free from defects before leaving the factory.

Gangben Mixer Factory has obtained multiple patents for the research and development of emulsifying machines and planetary mixers, as well as ISO quality management system certification and international CE certification. Our products meet quality standards with a reliable quality guarantee. We are committed to manufacturing high-quality mixing machinery to enhance your production efficiency and reduce costs for your company.

English

English Russian

Russian French

French Spanish

Spanish Portuguese

Portuguese Korean

Korean Japanese

Japanese Thai

Thai